Automated Sampling Checkweigher For Capsule Lines High-Accuracy Weight Checker

Checkweigher as known as check weigher, inline check weighing machine, weight checker, weight detection machine, weight sorting machine, sorting machine, weight check machine and etc,.

Designed for high-speed, non-destructive weight testing, the automated sampling checkweigher for capsule lines provides continuous, real-time feedback on product quality, sampling from the capsule filling machine without interrupting production, ensuring that each batch of capsules meets strict pharmaceutical standards. Automated capsule sampling from the high-accuracy weight checker increases production efficiency and facilitates batch verification, trend analysis and early detection of weight deviations, protecting consumers and brand integrity while reducing waste. You are welcome to contact us at any time for quotation.

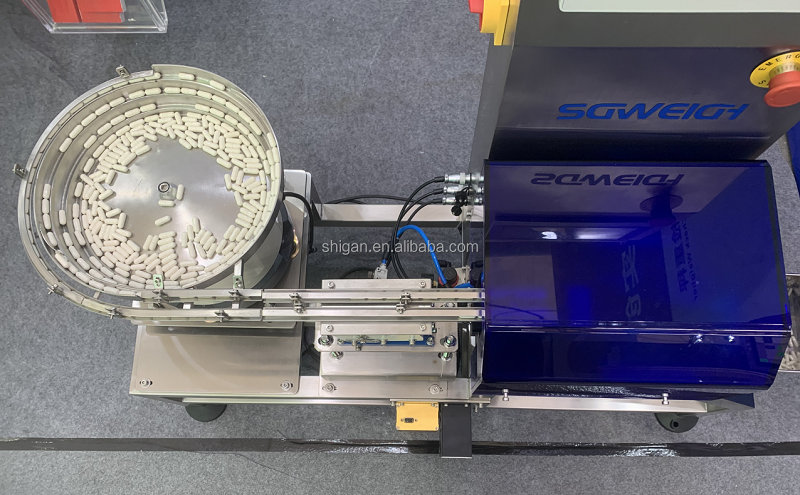

Automated sampling checkweigher for capsule lines pictures

Type SG-DJ10

Weighing Range 20-2000mg

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±1mg Depends on product

Division Scale 1mg

Each Channel Speed 100 pcs/min

Machine Weight 80kg

Power Supply AC -220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. Automatic random sampling during capsule filling process

2. High-precision sensor for non-destructive weighing

3. Easy to integrate with capsule filling equipment

4. Compact design, hygienic stainless steel

5. Real-time data collection for quality records

6. The automated sampling checkweigher for capsule lines is designed to optimize productivity, reduce downtime and ensure seamless and uninterrupted workflow.

The automated sampling checkweigher for capsule lines can check the weight of polished 000, 00, 0, 1, 2, 3, 4, 5 and extended capsules one by one without changing the mold; it can also be used to check the weight of tablets of various shapes and sizes one by one;

Automated Sampling Checkweigher For Capsule Lines High-Accuracy Weight Checker

To ensure that we will provide the right and qualified machine, please let us know more details about your project, such as material, weight range, speed, bag size, etc. We provide customized intelligent automatic packaging solutions, and we will be happy to help you find the best checkweigher.

Automated Sampling Checkweigher For Capsule Lines High-Accuracy Weight Checker

1> Attach safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packaging pieces;

3> Wrap tightly with plastic film;

4> Fix in plywood box

5> Forklift into container

Suitable for long-distance land and sea transportation. In order to safely load and unload to the destination, we recommend that you choose full container transportation.

Pre-sales service

1.Test customer engineer, learn how to use the machine.

2.With product samples and our machine.

3.Test machine video, will send to customers, then, pay the balance to us.

After-sales service

1.Manual.

2.Adjustment, setting video.

3.Telecommunication. Or face-to-face online communication is available.

4.This machine is under warranty for one year. During the warranty period, if there is no man-made damage, we will replace a new one for you. The warranty period will start from the machine shipped out and get the bill of lading.

Related Products

Pharma Sachet Checkweigher Conveyor System

Agriculture Heavy-Duty Checkweigher

Multi-Lane Packing Machine For Chemical Industry

Free-Fall Metal Detector For Grains Seeds

0# Capsules Dynamic Checkweighing System

Food Checkweighing Machines With Rejector

High-Speed Ketchup Multi-Lane Packing Machine

Dynamic Checkweigher For Bag Pork

Inline Metal Detector For Food Manufacturing

High-Speed Capsule & Tablet Metal Detector For Pharmaceutical

Hot Labels: automated,sampling checkweigher,capsule lines,high-accuracy,weight checker,factory,supplier,manufacture,price