Digital Capsule and Tablet Metal Detector Automatic Pharmaceutical Metal Detector

Digital capsule tablet metal detector has advanced sensitivity detects even the smallest ferrous, non-ferrous, and stainless steel contaminants, ensuring safe pharmaceutical production. Designed for efficiency, this automatic tablet and capsule metal detector performs fast inspections without sacrificing production efficiency. Its intelligent rejection mechanism immediately removes contaminated product, protecting equipment and ensuring consistent output. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Digital capsule tablet metal detector pictures

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

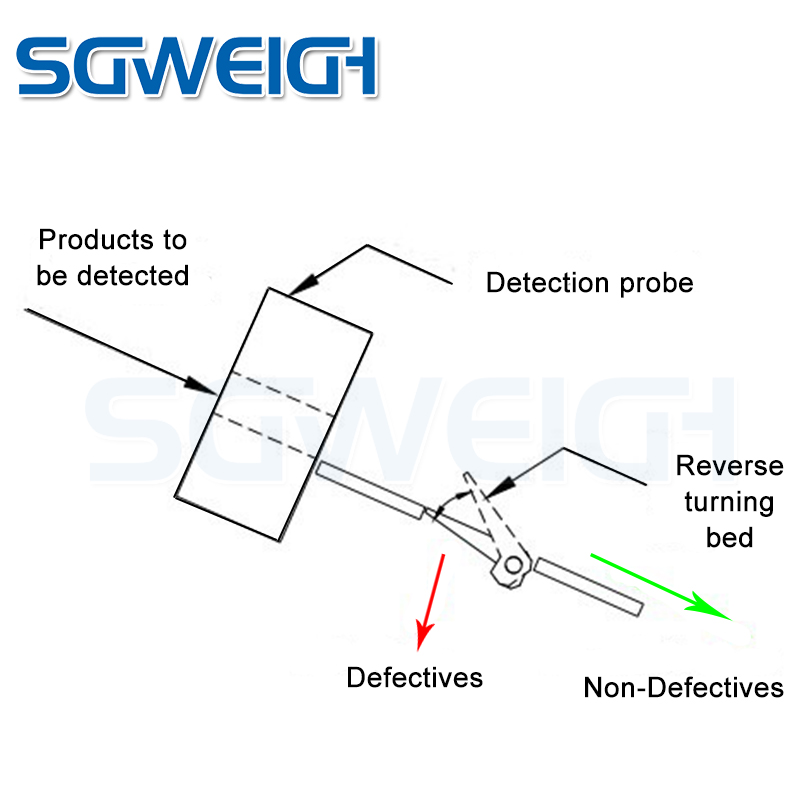

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

1. Utilizes the balancing principle for higher reliability.

2. Phase-adaptive technology adapts to the product and effectively eliminates product effects.

3. Utilizes a combination of DSP and a microprocessor to process test signal data, improving detection efficiency.

4. To prevent transmission and reception errors, the detector handles multiple operations. Test parameter adjustment is convenient.

5. Large LCD display with multiple languages, including Chinese and English, allows users to select as needed.

6. Features a self-learning function that automatically digitally learns and stores product characteristics. Operation is simple, eliminating the need for manual parameter adjustment.

7. Stores test data for over 100 products.

8. Automatic rejection system improves production efficiency and reduces labor costs.

Digital Capsule and Tablet Metal Detector Automatic Pharmaceutical Metal Detector

Digital capsule tablet metal detectors are suitable for capsules of various sizes and materials, providing reliable inspection for a wide range of products, including models #00, #01, #02, #03, #04, and #05.

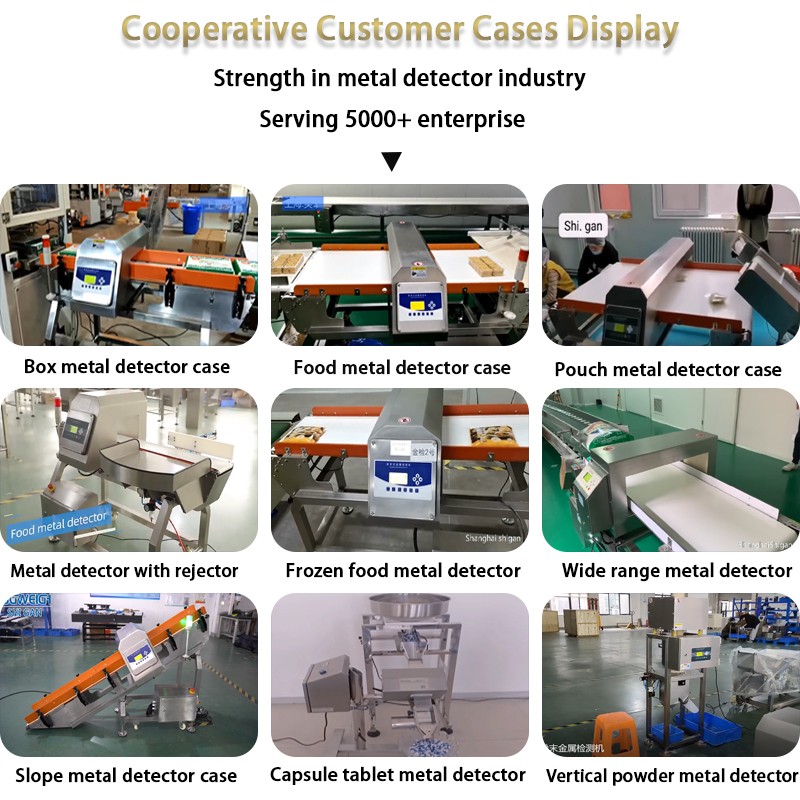

Each type of digital capsule tablet metal detector has its own specific application scenarios and advantages. Choosing the right one depends on production needs, item types, weight range, accuracy requirements, and other technical parameters.

Digital Capsule and Tablet Metal Detector Automatic Pharmaceutical Metal Detector

1> Attach safety labels, tighten screws, clean, lubricate, and rust-proof.

2> Disassemble into packages.

3> Wrap tightly with plastic film.

4> Secure in a plywood crate.

5> Load into the container by forklift. Suitable for long-distance land and sea transport. For safe loading and unloading at the destination, we recommend full container shipping.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* Factory tours.

After-Sales Service

* Machine installation and training.

* One-year warranty and lifetime repairs.

Related Products

Industrial Wide Range Checkweigher for 30kg Packaging

Multi-Lane High-Speed Sauce Packaging Machine

Heavy Bag Conveyor Checkweighing Machine

Industrial Checkweigher for Bottle Caps

Inline Capsule Tablet Metal Detector

Stainless Steel Precision Checkweigher for Pharma

Industrial Checkweigher for Missing Parts

High-Performance Coffee Multi-Lane Checkweigher

20kg Carton Box Packaging Checkweigher

Pharma Supplement Bottle Checkweigher Supply

Hot Labels: digital,capsule,tablet,metal detector,automatic,pharmaceutical metal detector,manufacturer,supplier,factory,price