Heavy-Duty Conveyor Checkweigher Large Range Checkweigher System for Industrial

This heavy-duty conveyor checkweigher features a reinforced conveyor system and high-precision load cells for accurate weight verification of products of various sizes and materials. Its wide weighing platform and adjustable speed control make it ideal for a wide range of packaging formats—from large bags of flour to fully loaded shipping boxes. Large range checkweigher system for industrial combines high-capacity weighing with fast throughput to handle high product loads continuously and uninterrupted. Delivering reliable performance and industrial-grade strength, you can count on it. To know more about us, please you do not hesitate to contact us or visit our factory.

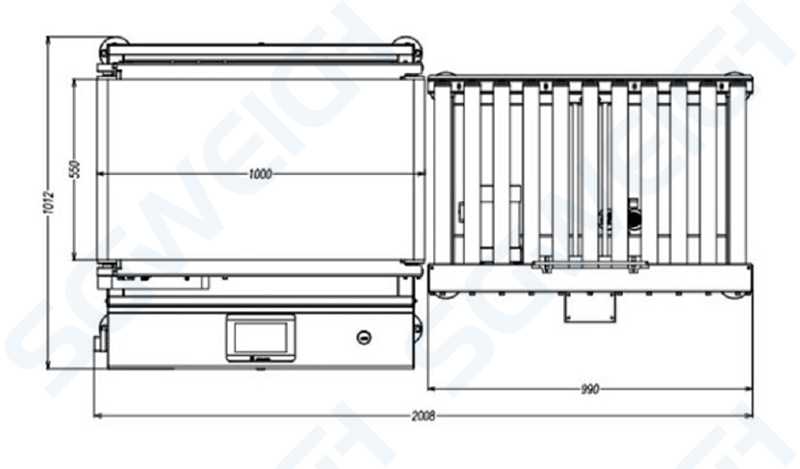

Heavy-duty conveyor checkweigher pictures

Type SG-600

Weighing Range 0.05-50Kg

Limited of product L: 800 W:550 H: 3-400mm

Accuracy ±20g Depends on product

Division Scale 1g

Belt Speed 0- 40 m/min

Max Speed 30 pcs/min

Belt Width 600mm

Machine Weight 80kg+50kg

Power Supply AC 110/220V ±10% 50HZ

Power 500W

Main Material SU304 stainless steel

Heavy-Duty Conveyor Checkweigher Large Range Checkweigher System for Industrial

1. Improved Production Efficiency: Heavy-duty conveyor checkweighers can automatically and quickly weigh and sort items, significantly improving production line efficiency and reducing manual operation time and errors.

2. Ensuring Product Consistency: Through accurate weighing, checkweighers help ensure consistent product weights, improve product quality, and meet customer needs and industry standards.

3. Reduced Waste: Heavy-duty conveyor checkweigher for industrial can promptly detect and sort items that do not meet weight requirements, reducing the circulation and waste of substandard products and lowering costs.

4. Improved Weighing Accuracy: Heavy-duty checkweighers utilize high-precision load cells, providing more accurate weighing results and helping businesses maintain precise inventory management and quality control.

5. Easy Integration: Large range checkweighers can easily integrate with existing production lines and automation systems, enabling unmanned or automated production lines with reduced human intervention.

6. Flexibility and Adjustability: Large range checkweigher system for industrial typically offer flexibility by allowing for adjustments to the weighing range and sorting criteria to suit the production needs of different products.

7. Data Logging and Analysis: Modern heavy-duty conveyor checkweighers often include data logging capabilities, allowing for the storage and analysis of weighing data, helping businesses track quality and improve production processes. High Reliability: Checkweighers are designed and manufactured with stability and reliability in mind, ensuring they maintain accuracy and stability during continuous operation, reducing downtime and maintenance costs.

8. Space Saving: Compared to traditional manual weighing methods, checkweighers can be installed more compactly on production lines, saving production space.

9. Adaptability: Large range checkweigher system for industrial can adapt to diverse operating environments, including harsh conditions such as temperature, humidity, and vibration, ensuring they remain functional in a variety of environments.

1) Packaged foods (e.g., cereal boxes, snack packs, frozen meals)

2) Beverages (e.g., juice cartons, milk cartons, bottled drinks)

3) Pharmaceuticals (e.g., pill boxes, blister packs)

4) Cosmetics and personal care products (e.g., shampoo bottles, lotion containers)

5) Household items (e.g., cleaning supplies, detergent containers)

6) Industrial products (e.g., hardware components, auto parts)

We are committed to solving every customer problem, meeting their needs, improving our products, and enhancing our service. We can also customize custom heavy-duty conveyor checkweighers based on customer needs.

Heavy-Duty Conveyor Checkweigher Large Range Checkweigher System for Industrial

Inner packaging is plastic film, outer packaging is a wooden or plywood box

Bare packaging with plastic film only and a plastic pallet.

We can provide fumigation packaging and certification.

Shipping options include: train, express delivery, or upon customer request.

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized, according to your product's features and your workshop environment, or your production line.

After-sales Service Provided

one year warranty and lifetime maintenance. During the warranty During the warranty period, accessories damaged by non-human factors will be replaced free of charge; outside the warranty period, accessories will be provided at cost.

Related Products

Multi-Row Liquid Sachet Packing Machine

High Sensitivity Plastic Bottle Metal Detector

Automatic Ultrafine Bottle Net Weight Checkweigher

Precision Capsule Packaging Line Checkweigher

Free Fall Metal Detector for Grains Cereals

Conveyor Belt Checkweigher With LCD Display

Real-Time Digital Metal Detector for Tablet

Box Fast Medicine Packaging Checkweigher

Multi-Row Powder Packing Machine for Food & Pharma

Automatic Checkweigher for Plastic Eyedrop Bottles

Hot Labels: heavy-duty,conveyor,checkweigher,large range,checkweigher system,industrial,manufacturer,factory,supply,price