Canned Clamping Conveyor Checkweigher, Quantitative Industry Roller Check Weigher Scales

Product Information

The clamping conveyor checkweigher is used for unsupervised inspection of product weight. It can automatically reject unqualified products. It is equipped with sound and light alarms, automatic recording and data storage. The quantitative check weigher can fully meet the needs of enterprises in the assembly line production process. For the quality management needs of less, missed, and more installed due to human error, we can realize unmanned, high-speed, and high-accurate quality control.For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Specification Parameter

TypeSG-150H

Weighing Range3-500g

Limited of productL: 100 W:150 H: 3-150mm

Accuracy±0.1g Depends on product

Division Scale0.1g

Belt Speed0- 90 m/min

Max Speed160 pcs/min

Belt Width150mm

Machine Weight60kg

Power SupplyAC 110/220V ±10% 50HZ

Power100W

Main MaterialSU304 stainless steel

We support customization, and our technicians will design the most efficient machine according to your specific requirements.

Following are the factors shall be taken into account during customization:

1,Products to be packed

2,Container to be filled, type and specification.

3. Capacity requirement

4. Automation requirement

5. Protection requirement

6,Other specific requirement

Main Advantages

1. Structural improvement: The center of gravity of the whole machine is moved down, and the chassis is more stable.

2. The display instrument can be rotated by 360° horizontally and 180° vertically, making it more convenient to watch the screen.

3. Self-directed sorting organization, the sorting speed is fast in the industry.

4. Better sealing performance, higher waterproof grade, stronger resistance to external interference.

5. Conveyor belt is easy to disassemble and install, convenient to install, repair and maintain.

6. Powerful data statistics storage function, which can pre-store 200 formula data and store tens of thousands of records.

7. The speed of the conveyor is adjustable to meet the requirements of the site and effectively ensure the working accuracy.

Application

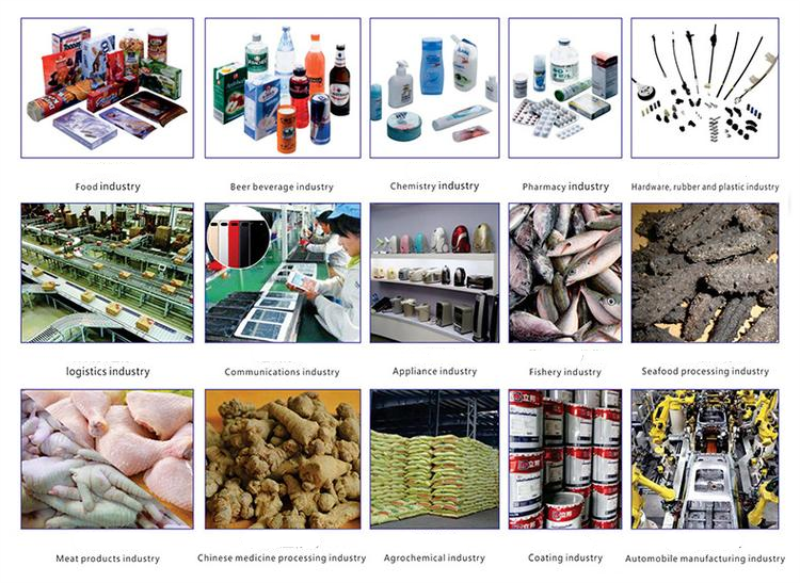

The high-precision checkweigher is widely used, and all quantitatively packaged products can be used. It is widely used in food, medicine, machinery, electronics, health products, agriculture, wine, chemical and light industry, building materials, energy, textiles, packaging, cosmetics, logistics, etc.

Canned Clamping Conveyor Checkweigher, Quantitative Industry Roller Check Weigher Scales

About Us

Shanghai Shigan Industrial Co., Ltd. is located in the beautiful scenery of Shanghai, China. It has been engaged in the production and development of assembly line weighing equipment since 2010, and has obtained CE certification and a number of professional certificates. The company has always been adhering to the "innovative, high-quality, and efficient" business philosophy. Provide you with perfect, high-quality products and services. Now our company's products have been sold all over the world, and have gained the trust and praise of countless customers!

Our main products are: digital metal detector,conveyor belt metal detector,automatic checkweigher metal dtector, checkweigher, high-speed and high-precision checkweigher, and a series of assembly line packaging testing equipment

Canned Clamping Conveyor Checkweigher, Quantitative Industry Roller Check Weigher Scales

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: to win customer satisfaction with high-quality service quality

3. Service efficiency: If the equipment fails during the warranty period or outside the warranty period, we will provide you with a solution in the first time.

4. Service principle: The product warranty period is twelve months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons free of charge. If the parts are damaged outside the warranty period, only the cost of the parts provided will be charged. For equipment damage caused by human factors on the demand side, the repair or accessories provided by the supplier will be calculated at cost.

5. After the warranty period, our company's sales staff will return visits to investigate user usage no less than three times a year.

Related Products

Oil Vertical Liquid Quantitative Filling Packaging Machine

Non-Sticky Granule Packaging Machine

Dynamic Automatic Non-falling Bottle Checkweigher Machine

Intelligent Weighing Labeling Machine

Automatic Metal Detector For Daily Necessities

15kg Intelligent Sorting Checkweigher

Hot Labels:canned,clamping,conveyor,checkweigher, quantitative,industry,roller,check weigher,scales