Check Weigher and Metal Detector Combination High Quality Industrial Conveyor Belt

The check weigher and metal detector combination is a combination of a metal detection head and a checkweigher in one frame, effective and space-saving, providing excellent and reliable product inspection in a compact design. With a single centralized control panel, checkweigher and metal detector technology is fully integrated into one solution, the checkweigher metal detection machine solution is available in a wide range of configurations to suit every space requirement.Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

Check weigher and metal detector combination photos

Type Digital Checkweigher With Metal Detector Combo

Model SG-JS150

Specifications 4010

Detection of hole width detection 150mm

Inspection hole height 100-200mm

Detection sensitivity

In empty state:(H)100mm ;Fe≥Φ0.8mm,SUS≥Φ1.2mm

(H)120mm ;Fe≥Φ1.0mm,SUS≥Φ1.8mm

(H)150mm ;Fe≥Φ1.2mm,SUS≥Φ2.0mm

(H)200mm ;Fe≥Φ1.5mm,SUS≥Φ2.5mm

Effective hole width detection 150mm

Effective hole detection level 100-200m

Weighing accuracy ±0.1g(Depend on product)

Conveyor height 750mm(±50mm)

Transmission capacity 10kg/times

Transfer direction From left to right

Conveyor belt max speed 25m/min

Material for conveyor belt Food grade PU belt

Protection grade IP65

Display and operation mode LCD flat key input

Deadweight of machine About 240kg

Power supply requirements AC 220V 50HZ

Power About 300w

Overall dimensions About L2267*W589*H1500mm(Design drawing prevail)

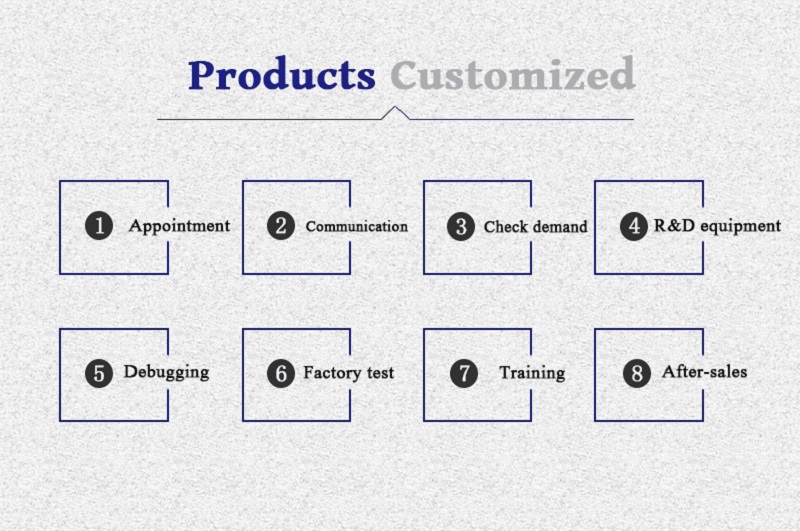

Customized solutions to meet complex needs:

There is no identical production line. Our professional engineers will rigorously evaluate factors such as production line characteristics, specifications and environment, and design the most suitable check weigher and metal detector combination solution for your production line to meet the different needs of various complex production lines.

The check weigher and metal detector combination can be widely used in food, pharmaceutical, chemical, textile, clothing, toys, rubber and other fields after packaging weight and metal detection. It is the first choice for HACCP certification in the food industry and GMP certification in the pharmaceutical industry.

1. Reverse detection: The use of high-precision imported through-fire switches, combined with curve fitting algorithms, can accurately complete reverse detection

2. Customization ability: can be equipped with a scanning gun to meet various special requirements for deep customization and function development

3. Simple and intelligent operation: With wide LCD and wizard interface, users can easily set and operate

4. Reliable data: FRAM storage technology is used to ensure system parameters and data

5. Advanced manufacturing process: The metal detector adopts all stainless steel probes and racks, and a variety of protection levels are available for customers to choose from, adapting to various production environments

6. Anti-deviation design of conveyor belt: The metal detector adopts a special anti-deviation design scheme of conveyor belt, which can effectively avoid the deviation of conveyor belt.

7. Abundant peripheral interfaces: RS-485 data communication, PLC programming node, and printer output can be configured, which can provide real-time data for the production management system for remote control, analysis and monitoring, and provide valuable traceability information

8. Rejection device: equipped with blocking arm type, blowing type, flap type, push rod type and other rejection devices

We are committed to providing quality products and services to our customers and society. - Shanghai hard work

Shanghai Shigan Industrial Co,.Ltd has more modern working facilities and gained expertise and experience in various digital metal detection, automatic weighing detection. We are becoming a high-tech enterprise integrating R&D, production, marketing and service backup. The main products include automatic weighing machines, metal detectors and other complete line checkweighing solutions, which are widely used in snack food, puffed food, fresh frozen Food, agriculture, medical, chemical and hardware fields.

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 20 days after payment

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality to win customer satisfaction

3. Service efficiency: If the equipment fails within the warranty period or outside the warranty period, our company will arrange maintenance personnel to perform maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, only the cost will be charged for the accessories provided. If it is due to human factors For equipment damage caused, our company repairs or provides accessories at cost price.

Related Products

Assembly Line Single Piece Mask Checkweigher

Dynamic Boxs Check Weigher and Rejector

Metal Detection Machine With Conveyor Belt

Highly Sensitive Metal Detector With Touch Screen

Daily Necessities Production Line Metal Detector

Industrial Conveyor Belt Type Metal Detector for Food

Hot Labels:check weigher and metal detector combination,high quality,industrial,conveyor,belt,checkweigher metal detection machine,factory,Egypt