Digital Metal Detection Machine for Capsules & Tablets in Pharma Industry

Metal detection machine for capsules tablets detect all types of metals including ferrous metals, stainless steel, aluminium, copper and brass by inspecting pills and capsules. Digital metal detection machine for pharma reliably detect free or encapsulated contaminants in the product stream. Contaminants are detected and automatically removed from the product stream without interrupting the process. You are welcome to contact us at any time for quotation.

Metal detection machine for capsules tablets pictures

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

1. High Sensitivity: Detects a wide range of metals, including ferrous, non-ferrous and stainless steel.

2. Accurate Detection: Minimizes false positives and reduces product waste.

3. Easy Integration: Compatible with existing production lines.

4. Compliance: Meets pharmaceutical safety and quality regulatory requirements.

5. Durability: Withstands harsh production environments.

Digital Metal Detection Machine for Capsules & Tablets in Pharma Industry

We support OEM/ODM. When using the metal detection machine for capsules tablets, you also need to tailor a machine that meets your usage needs based on the specific requirements of the capsule and the actual production environment.

Suitable for pharmaceutical industry, such as tablets, capsules, powders, pills, etc.

The equipment is packed in export standard wooden boxes (fumigation-free), which meets international transportation requirements and can ensure the safety and reliability of the equipment during transportation.

Digital Metal Detection Machine for Capsules & Tablets in Pharma Industry

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer questions encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain the products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of accessories to meet user needs.

4. One-year warranty, lifetime maintenance

Related Products

High Accuracy Capsule Tablet Metal Detector

High Precision Tablets & Capsules Checkweigher

Automatic Multi-Rows Tomato Paste Packing Machine

Hard Capsule Production Line Checkweigher

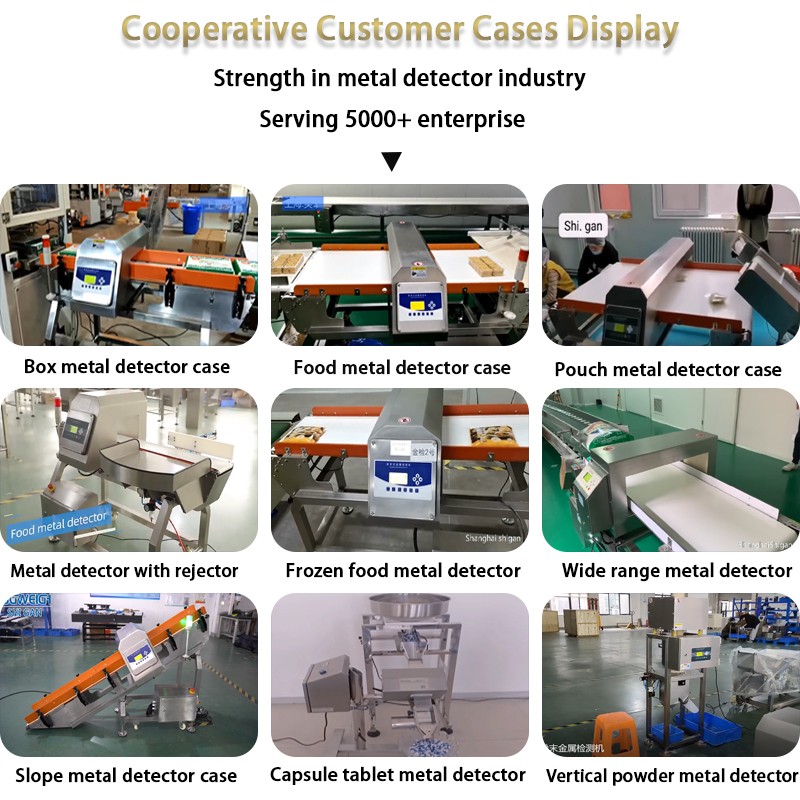

Carton Box Metal Detector Machine for Industrial

Granulated Feed Vertical Metal Detector

Box High Speed Check Weigher Ecomonic Checkweigher

20ml Paste Pouch Multi-lane Checkweigher

Efficient Multi-Lane Granule Packaging Machine

Box Metal Detector for Pharmaceutical

Hot Labels: digital,metal detection machine,capsules,tablets,pharma industry,price,manufacturer,supplier,factory