Dynamic Bag Box Packaging Checkweigher Automatic Packaging Check Weigher

Checkweigher also called check weigher, check weight machine, check weighing machine, weight sorting machine, weight checker, and etc,.

The automatic packaging check weigher system features a built-in dynamic weighing sensor and automatic rejection mechanism that operates seamlessly at high speeds while maintaining strict accuracy standards, verifying the weight of various packaging formats, from soft bags to cartons, in real time. The dynamic bag box packaging checkweigher brings intelligence to your production line, and the intuitive interface features customizable product settings, data tracking and real-time diagnostics. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

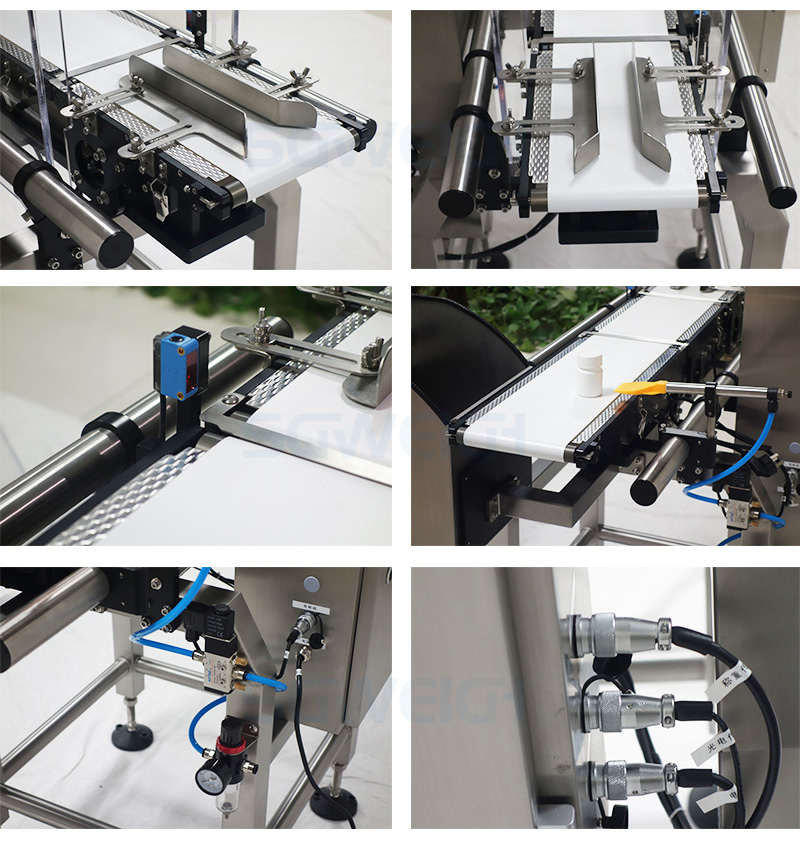

Automatic packaging check weigher system pictures

Dynamic Bag Box Packaging Checkweigher Automatic Packaging Check Weigher

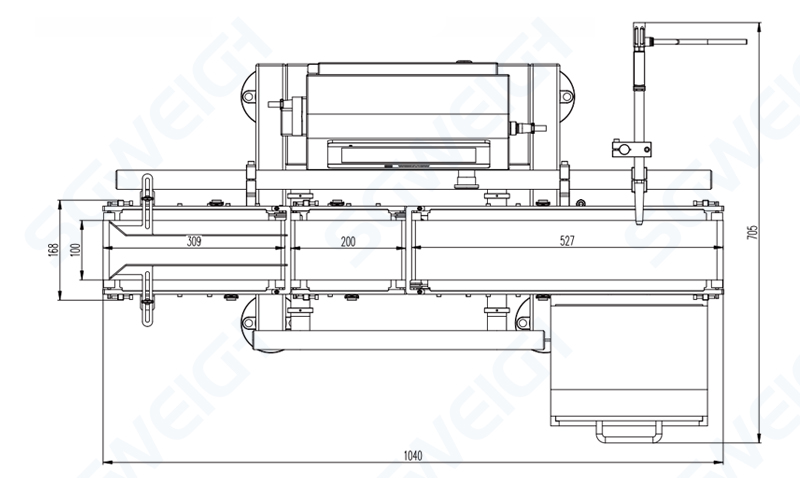

Type SG-100

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.05g Depends on product

Division Scale 0.01g

Belt Speed 0- 90 m/min

Max Speed 260 pcs/min

Belt Width 100mm

Machine Weight 70kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1.High performance and maximum efficiency.

2.Large load range with extreme precision.

3.Designed for demanding production environments.

4.Flexible and efficient product handling.

5.Low maintenance costs.

6.Improve production line efficiency. Equipment efficiency across the entire line is improving.

7.The accuracy of the weighing machine ensures that customer interests are not affected.

8.Reduce potential sampling errors and long-term labor costs.

9.Improve product quality to meet customers' strict needs.

10.Cost savings increase product profits.

This automatic packaging check weigher system is exclusively customized according to customer requirements and may not meet your requirements. Our company's digital metal detector is factory-supplied and provides non-standard customized equipment. We provide a variety of metal detector solutions free of charge. Please feel free to contact us.

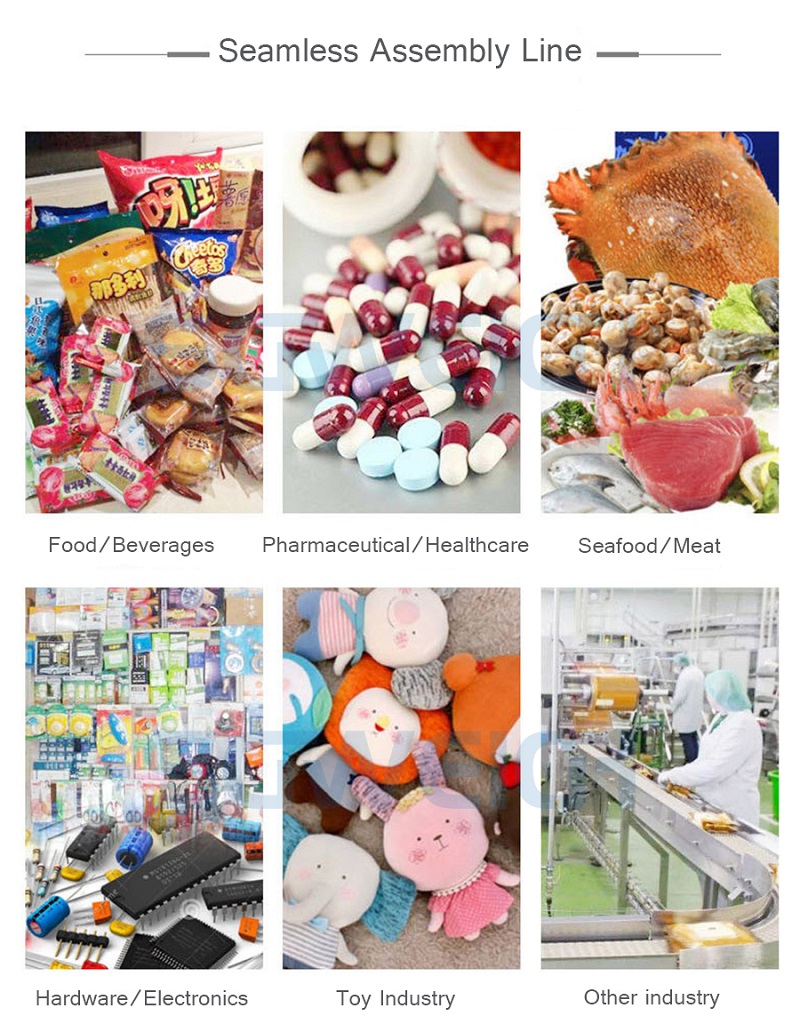

It is an automatic packaging check weigher system widely used in production lines in the pharmaceutical, food, chemical and other industries. It can detect overweight and underweight unqualified products in the production line in real time and automatically remove unqualified products.

Dynamic Bag Box Packaging Checkweigher Automatic Packaging Check Weigher

Packaging

Film pack inside, Wooden case outside

Shipping

1. Upon receipt of payment, delivery date will be in 20-30 working days

2. By Air, by Sea or by Express (DHL, UPS, TNT, EMS, etc.)

1. Equipment installation and commissioning: The company provides a detailed operation manual and free operation training to ensure that customers can use the equipment proficiently.

2. Technical support: The company provides 24-hour technical support to solve problems encountered during use for customers.

3. Accessories supply: The company provides original accessories to ensure the quality and stability of accessories.

4. Quality assurance: The company is responsible for the products sold to ensure that the quality and performance of the equipment meet industry standards.

5. Warranty policy: One-year warranty, lifetime maintenance, to solve worries for customers.

Related Products

High-Precision Tablet Metal Detector For Pharma

Mini Compact Checkweigher for Tablet

Liquid Pouch Multi-Lane Packaging Machine

Automatic Canned Food Checkweigher With Rejector

Manual Missing Detection Checkweigher

Eye Drops High Speed Checkweigher for Pharma

Online Dual-Lane Checkweigher For Strip Package

Full-Box Beverage Weight Detection Checkweigher

High Speed Tubed Products Checkweigher

Boxed Milk Online Checkweigher Production Line

Hot Labels: dynamic,bag,box,packaging,checkweigher,automatic,packaging,check weigher,supplier,factory,manufacturer,price