High Speed & Accuracy Measurement Checkweigher Box Weight Checker Price

By adding a high speed & accuracy measurement checkweigher to the production line, product quality can be improved without reducing efficiency. In order to ensure that the nominal weight of the packaged items is consistent with the actual weight, the fully automatic box checkweigher can check all packaged items in batch production, so that unqualified products cannot enter the circulation field, effectively safeguarding the interests of consumers. You are welcome to contact us at any time for quotation.

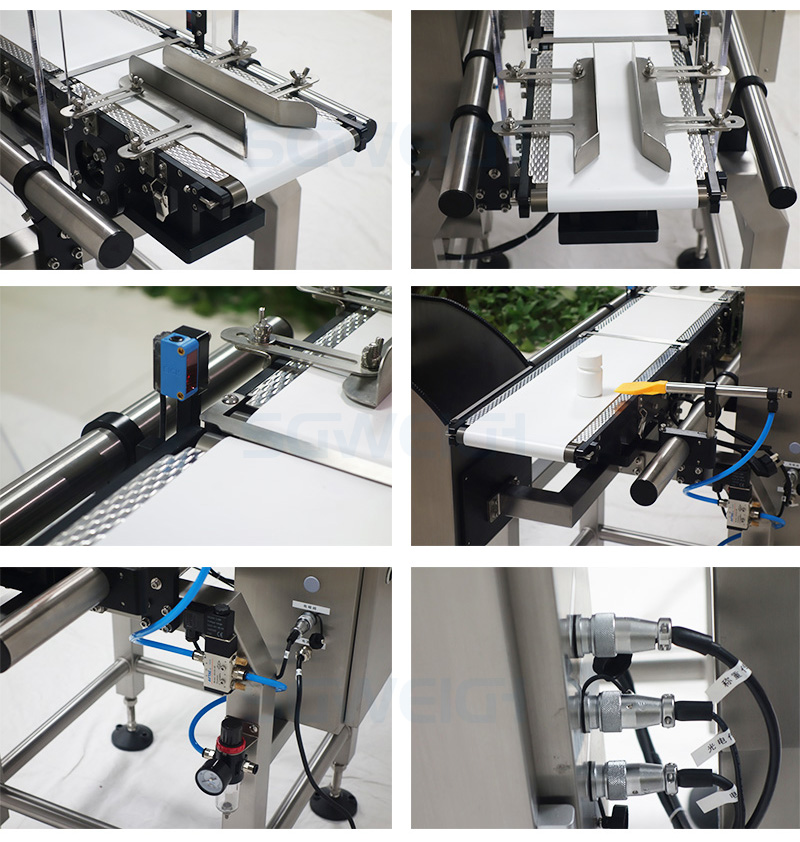

Box checkweigher with high speed pictures

Type SG-150U

Weighing Range 3-500g

Limited of product L: 100 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 60kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. Intelligent design, automatic parameter adjustment, easy operation.

2. Material density alarm, automatic generation of column production report.

3. The conveyor structure adopts a detachable design, which is easy to disassemble and clean.

4. PLC control system, standard industrial control screen, easy to expand other value-added applications, such as multi-level weight sorting, weight feedback, etc.

High Speed & Accuracy Measurement Checkweigher Box Weight Checker Price

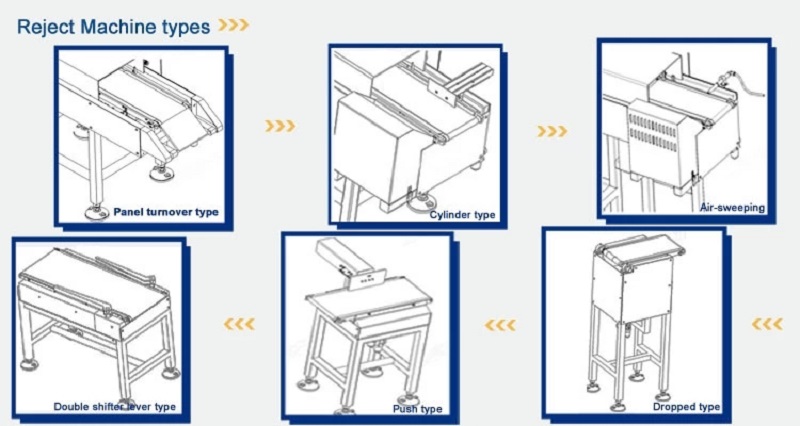

In the application of assembly line checkweighers, Shanghai Shigan provides the following customized services to users in various industries:

1) Help users choose the checkweigher model that suits the current status of the production line;

2) Customize weight detection or quality abnormality solutions for users;

3) Design economical and practical online checkweigher solutions for users;

4) Customize the front-end and back-end connection auxiliary mechanisms of assembly line weight detection equipment for users;

5) Provide users with consulting and training services for assembly line checkweighers.

High speed & accuracy measurement checkweighers are widely used in many industries such as electronic hardware, pharmaceuticals, food, chemicals, beverages, health products, etc. They can be used for parts missing detection, package missing detection, box missing detection, bottle missing detection, can missing detection, bag missing detection, etc.

High Speed & Accuracy Measurement Checkweigher Box Weight Checker Price

Machine packing :

Non-fumigation wooden case for export standard and comply with customs clearance requirement

Lead time :

10-15 days after payment received

Price term :

FOB term, CIF/CFR term(sea/air), DDU/DDP term( sea/air)

Negotiable payment term: T/T , LC, D/P ,D/A .,etc

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer questions encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain the products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of accessories to meet user needs.

4. One-year warranty, lifetime maintenance

6. After-sales service tracking: Track and feedback the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

High-precision Four-side Sealing Multi-lane Packaging Machine

Stable Heavy Carton Check Weigher for Industrial

Online Standup Pouch Missing Part weight Checking Solution

SHIGAN High Accuracy Capsule Tablet Check Weighing Machine

Multi Lane Powder Packing Machine for Mixed Spices

Digital Food Metal Detector for Vegetables

Bottle Capsule Check Weigher with Rejection System

Inline Snack Candy Bags Conveyor Mini Checkweigher

Hot Labels: high speed,accuracy measurement,checkweigher,box,weight checker,manufacturer,price,supply