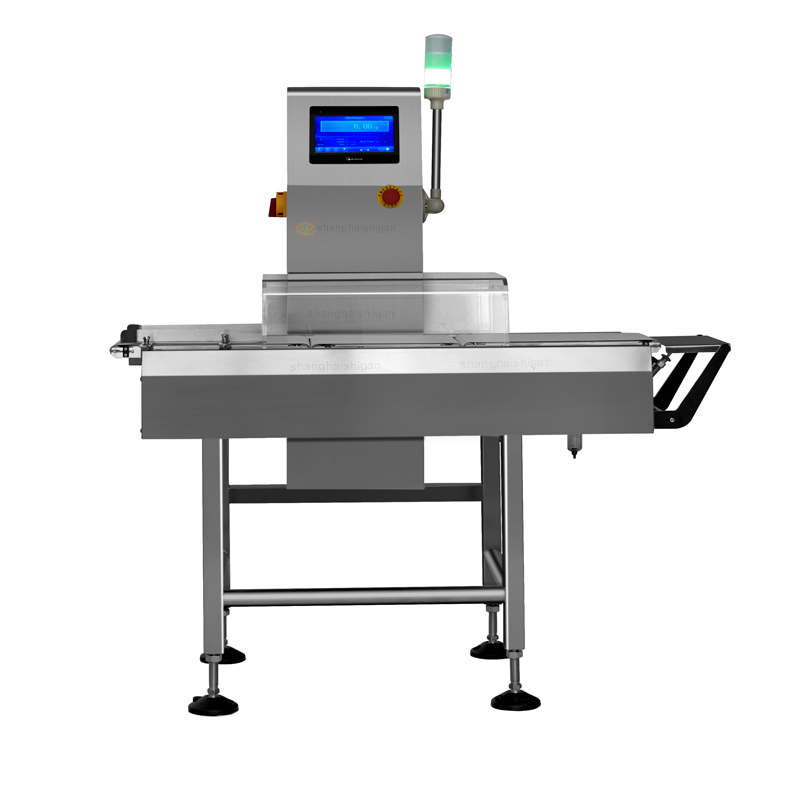

High-Speed Frozen Food Checkweigher Packaging Lines Hygienic Stainless Steel Checkweigher

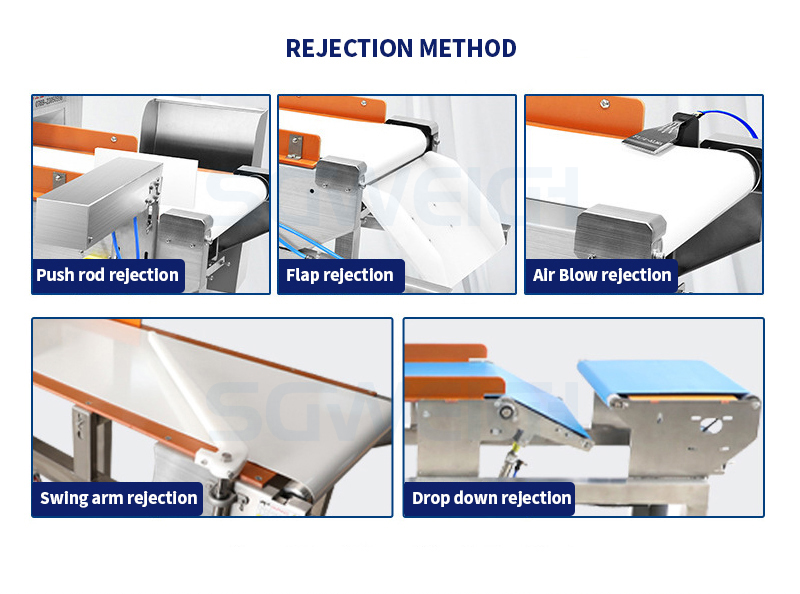

This high-speed frozen food checkweigher provides real-time, highly accurate measurement, instantly detecting under- or overweight packages, avoiding costly errors and safeguarding brand reputation. The packaging line food checkweigher system seamlessly integrates into conveyor lines, providing continuous monitoring and automatically rejecting non-compliant products. Adjustable weight settings quickly accommodate a variety of product sizes and packaging formats, from bulk frozen packs to single-serve packs. You are welcome to contact us at any time for quotation.

High-speed frozen food checkweigher pictures

1. 10" color LCD touchscreen display for easy operation

2. High-speed, high-precision, and high-accuracy load cells ensure accuracy

3. 250 product presets for easy editing and recall

4. Three-tier client login and user rights management with password protection for all data

5. Weight list output via USB port; standard RS232 port available

6. Automatic or manual zeroing

7. PLC control system ensures system stability

8. Quick-release locks and fasteners make the conveyor easy to assemble, inspect, and clean.

9. Stainless steel construction for easy cleaning

10. RS485 and LAN ports available

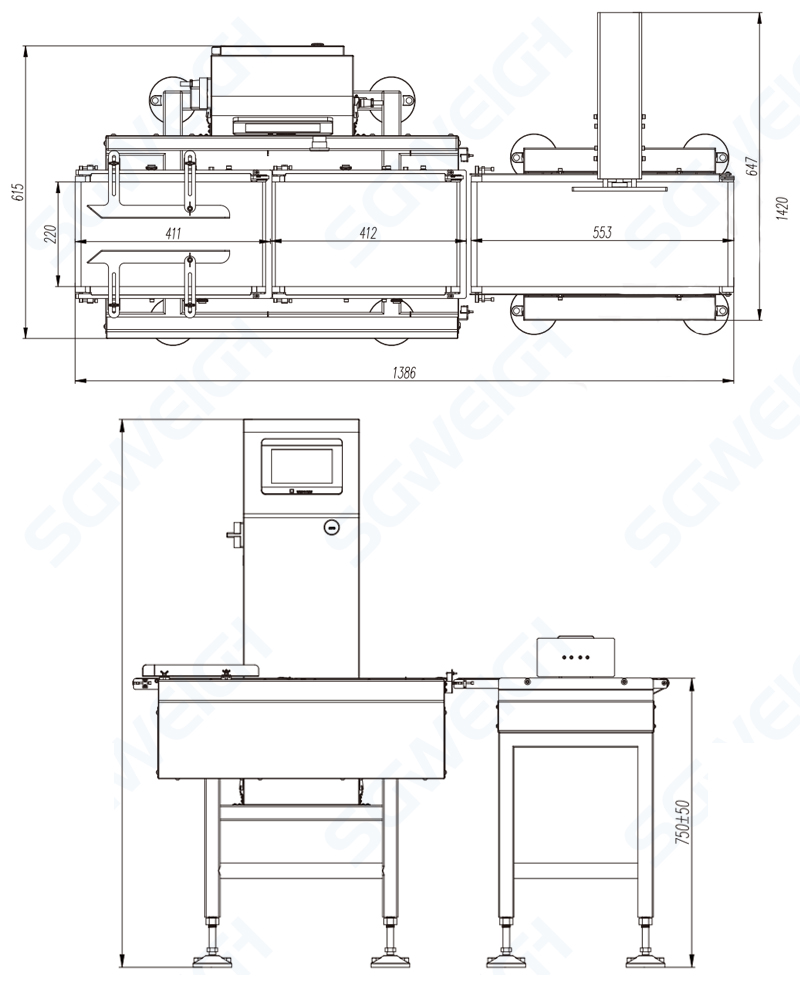

Type SG-220U

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width 220mm

Machine Weight 65kg

Power Supply AC-220V 50HZ

Power 200W

Main Material SU304 stainless steel

High-Speed Frozen Food Checkweigher Packaging Lines Hygienic Stainless Steel Checkweigher

High-speed frozen food checkweighers are widely used in a variety of industries, including pharmaceuticals, food, beverages, daily chemicals, light industry, electronics, hardware, industrial products, Chinese medicinal materials, aquatic products, poultry, fruits and vegetables, and logistics.

We are committed to solving every customer problem, meeting customer needs, improving our products, and enhancing our service. We can customize non-standard high-speed frozen food checkweighers according to customer needs.

High-Speed Frozen Food Checkweigher Packaging Lines Hygienic Stainless Steel Checkweigher

Plastic packaging is used internally, and a sturdier wooden box is used for external packaging.

Our Standard Packing Process:

1) Dust removal and cleaning

2) Lubrication of drive components

3) Divide the machine into modules

4) Wrap the modules with plastic film

5) Pack the modules into plywood boxes

6) Mark the box with shipping mark.

If you have any special requirements, we will package them accordingly.

1. Pre-sales consultation

We will help you customize the appropriate weighing and packaging solutions according to your requirements and specific circumstances.

2. Installation service

We will dispatch professional technicians to carry out on-site installation and commissioning as needed.

3. Maintenance Service

Shigan provides long-term repair services, providing all repair parts free of charge during the warranty period. No charge will be made after the warranty expires.

4. Employee Training

Shigan provides free technical training to our customers to fully master proper product maintenance techniques.

5. Customer Service

Shigan designs customized production lines based on specific weighing and packaging factors, such as product output, packaging method, and factory space.

Related Products

Stick Pouch 6-Lane Checkweigher for Food & Pharma

Cosmetics Multi-Line Packaging Machine for Mask Powder

Online Capsule Tablet Sampling Checkweigher

Industrial Food Metal Detector for Sheet Gum

Industrial Metal Detector and Checkweigher Combo

Accurate Pharmaceutical Bottle Checkweigher

High-Accuracy Metal Detection Machine for Pharmaceutical

Bottle Production Line Checkweigher

Nutraceutical Capsule Tablet Checkweigher

Dynamic Cosmetic Packaging Checkweigher

Hot Labels: high-speed,frozen food,checkweigher,packaging lines,hygienic,stainless steel checkweigher,manufacturer,price,supply