Industrial Checkweigher for Box Processing Production Line Inline Check Weigher

This industrial checkweigher for box production line is designed for harsh industrial environments, maintaining stability even at high speeds. Seamless online integration ensures smooth production, while a robust frame and shock-resistant conveyor system guarantee stable performance during extended production runs. Inline box processing check weigher verifies the weight of each carton in real time, ensuring precise weight control, while an automatic rejection system immediately removes defective cartons. You are welcome to contact us at any time for quotation.

Industrial checkweigher for box production line pictures

Type SG-150H

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 90 m/min

Max Speed 250 pcs/min

Belt Width 150mm

Machine Weight 70kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

The industrial checkweigher for box production line shown may not meet your requirements. We have professional technicians who can provide customized solutions based on your product characteristics and application scenarios.

1. Reporting Function: Built-in report statistics; reports can be generated in EXCEL format, and various real-time data reports can be automatically generated. A USB flash drive can store more than one year's worth of statistical data (required), allowing for real-time monitoring of the industrial box checkweigher's production status.

2. Interface: Standard interfaces are reserved for convenient data management, enabling connection to communication networks and intelligent devices such as PCs.

3. Centralized Control: Enables centralized control of multiple industrial checkweighers for box production lines from a single computer/HMI.

4. Parameter Recovery Function: Includes factory parameter setting recovery.

5. Versatility: Standardized machine structure and standardized HMI allow for weighing various materials.

6. Easy Replacement: Stores multiple formulas for easy product specification changes.

7. Simple Operation: Utilizes a Weintek color HMI, featuring overall intelligent and user-friendly design.

8. Easy Maintenance: The conveyor belt is easy to disassemble, install, maintain, and clean.

9. Speed Adjustment: Employs a variable frequency drive (VFD) motor, allowing for speed adjustment as needed.

10. High Speed and High Precision: Utilizes high-precision digital sensors.

11. Zero-Point Tracking: Allows for manual or automatic zero-point clearing and dynamic zero-point tracking.

Industrial Checkweigher for Box Processing Production Line Inline Check Weigher

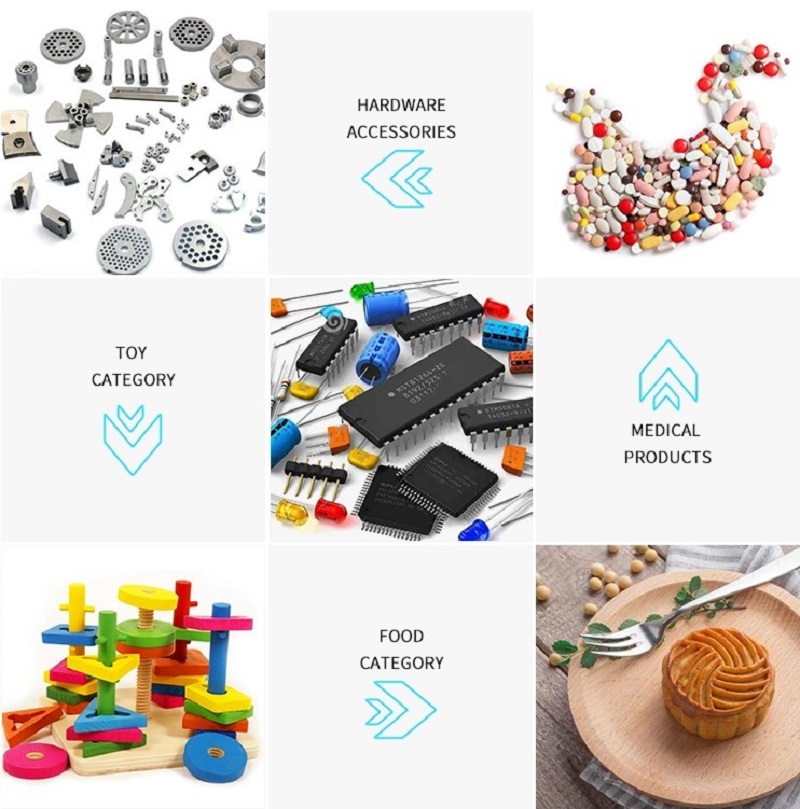

Industrial checkweigher for box production lines are widely used in many industries such as pharmaceuticals, food, beverages, daily chemicals, light industry, electronics, hardware, industrial products, traditional Chinese medicine, and logistics.

Industrial Checkweigher for Box Processing Production Line Inline Check Weigher

1> Affix safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Unpack into individual packages;

3> Wrap tightly with plastic film;

4> Secure in plywood crates;

5> Forklift into the container. Suitable for long-distance land and sea transport. For safe loading and unloading at the destination, we recommend full container load (FCL) shipping.

A.Pre-sales

project design,performance introduction,technical agreement,contract signing,production testing and we can customized production according to your requirements.

B.In-sales

we will provide you with the latest process in the product assembly,packing and transportation.

C.Installation

1.We provide videos and instruction manual to show the process of installation.

2.We provide training for installation for free in our factory.

3.We can send technician to buyer's factory to install the machine and provide training service.

D.After-sales

1. For our machines, we will provide some spare parts and easy broken parts free of charge when delivering.

2.We will have one year free warranty period. During warranty period, if there is any malfunction for the machine, we will try our best to solve the problem within 24 hours. If there are some spare parts needed to be replaced, we will provide the spare parts for free. Beyond warranty, we will charge the cost price for spare parts.

3.We provide technical support for our machines for life-long time. We can provide installation and maintenance service at your place if you need.

Related Products

Liquid Energy Gel Multi Track Packing Machine

Vertical Free Fall Type Metal Detector Systemm for Food Powder

High Speed Checkweigher for Box-Pack

Capsule Tablet Metal Detector for Pharmaceutical & Nutraceutical

Dual-Channel Capsule Weight Sampling System

High-Precision Protein Bar Checkweigher

All-in-One Checkweigher and Metal Detection Machine

Tablets Vertical Metal Separator Combined De-duster

Plastic Bag Sauce Multi-Lane Packing Machine

Carton Bag Checkweigher for Packaging Lines

Hot Labels: industrial,checkweigher,box,processing,production line,inline,check weigher,quote,solution,manufacturer,supplier,factory,price