Industrial Metal Detectors for Plastics Conveyor Belt Metal Detection

The industrial metal detectors is an intelligent metal detection equipment developed using digital intelligent technology, which realizes the full digitization and intelligence of metal detection technology. Digital conveyor belt metal detection machine is used to detect various metal impurities such as metal chips, broken needles, iron wires, lead, copper, aluminum, tin, stainless steel, etc. that are mixed or lost in raw materials or products. Excellent performance, simple operation, and wide application industries. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Industrial metal detectors photos

1. Stable high detection accuracy, mature digital phase modulation technology, effectively suppressing product effects, making the system have stable high detection accuracy;

2. Automatic setting function, simple and fast parameter setting, the system can automatically analyze product characteristics and calculate appropriate detection parameters;

3. User level management function, setting passwords suitable for different user levels for different positions, clarifying permissions and responsibilities, and facilitating management;

4. Database function, product database, automatic counting library, detection information recording library, can quickly achieve product switching and historical data retrieval;

5. Humanized design, equipped with an intelligent operating system, a 7-inch LCD color touch screen, with simple and intuitive operation, allowing for easy human-machine dialogue;

6. Printer interface, the system has a printer interface, which can print real-time detection information through the printer, and the data can be viewed intuitively and clearly;

7. Supports built-in high-capacity SD cards to store more data (including detection record data, product configuration data, etc.), meeting the requirements for large data volume (optional);

8. Support data export function through USB drive.

Machine Grade:Food Grade

Detecting width:400, 500 mm (can be customized)

Detecting height:80, 100, 120, 150, 200, 250, 300, 350 mm (can be customized)

Detecting sensitivity:Fe 0.8mm-3.0mm, Non-Fe 1.2mm- 4.0mm;Stainless Steel 1.5mm- 5.0mm

Display Screen: 7inch (optional)

Sensitivity adjustment:100 level adjustment

Detecting adjustment: Intelligent adjustable

Belt Speed:20m /min (or specified)

Alarm mode:The buzzer alarm, the motor automatically stop

Power:AC22V,50Hz (Or Customized)

The display model is a customized model for customers, which may not meet your requirements. The above parameters are for reference only. Shanghai Shigan has over 15 years of experience in digital metal detection machine for industrial manufacturing, and can provide multiple sets of digital metal detection machine solutions for free according to your actual needs!

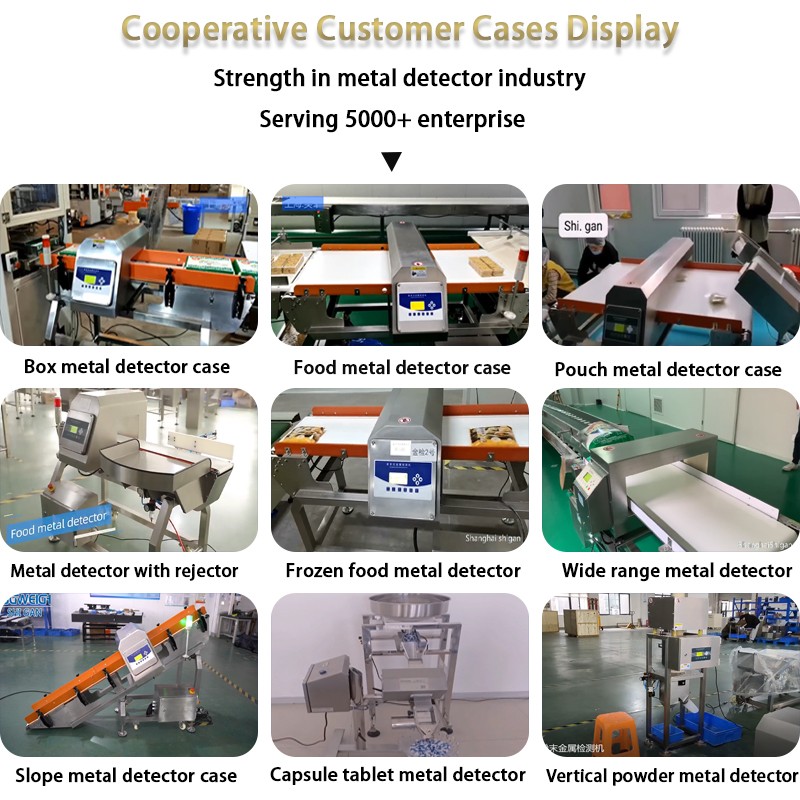

Industrial metal detectors is widely used in industries such as food, medicine, aquatic products, toys, clothing, footwear, chemicals, leather, knitting, printing, etc. to detect metal impurities mixed in products or raw materials during the production process.

Shanghai Shigan Industrial Co., Ltd. was established in 2010 and is a high-tech enterprise specializing in the field of digital metal detection machine, automatic checkweigher equipment. The company is mainly committed to the research and development, production, and sales of assembly line equipment such as digital metal detection machine, automatic checkweigher equipment. After more than ten years of development, Shanghai Shigan has become a well-known equipment manufacturer and service provider in the industry.

The company's products cover digital metal detection machine, automatic checkweigher, weighing and labeling machines, and are widely used in multiple industries such as food, medicine, chemical, and logistics. In order to meet the constantly changing needs of customers, Shanghai Shigan places great emphasis on cultivating independent research and development capabilities and building a technical team. The company has formed a technical team with independent research and development capabilities, providing customers with continuous technical support and innovative products.

The equipment will be securely fixed and then packed into wooden cases for protection during transportation.

Fast delivery guaranteed! The earliest delivery time is 5 days after payment.

A. Pre-sale:

1. Provide real quotations for customers according to customer requirements, and timely record feedback when customers have special requirements;

2. Sign a standardized product order contract, clarify responsibilities and other related matters;

3. Provide one-year free warranty, lifetime maintenance service, and be responsible for debugging the product before shipment;

B. After sale:

1. If the customer's product fails, we will provide you with a solution as soon as possible;

2. During the warranty period, the product is repaired free of charge. If the warranty period is exceeded, repairs can also be provided. If the parts are replaced, the product parts will be provided at the cost price.

Related Products

Vertical Metal Detector for Robust Capsule Tablet Pill

Dynamic Carton-Line Checkweighers Heavy Case

Shrimp Automatic Multi-stage Sorting Checkweigher

Digital Checkweigher and Metal Detector Combination

Online Single Pills Tablets Capsules Checkweigher

Automatic Check Weigher for Bags Online Industrial

Hot Labels:industrial,metal detectors,plastics,conveyor,belt,metal detection machine,factory,supply,manufacturer