Intelligent Checkweigher and Metal Detector Combo for Production Lines Solution

Checkweigher and metal detector combo as known as weighing metal detection machine, check weigher with metal detection machine, weight checker metal detector, and etc,.

The intelligent checkweigher and metal detector combination is a high-performance solution designed to enhance your production line by ensuring weight accuracy and contamination-free products. This combined system optimizes production efficiency through simultaneous dual detection, while an automatic reject system ensures that any underweight, overweight, or contaminated products are immediately rejected. The checkweigher and metal detector combo for production line is intuitive and easy to integrate. Its touchscreen interface enables operators to monitor line performance, adjust settings, and review inspection data in real time. You are welcome to contact us at any time for quotation.

Intelligent checkweigher and metal detector combination pictures

1. High-precision load cells ensure consistent and accurate measurements

2. Real-time dynamic weighing for continuous process monitoring

3. Automatic rejection of non-compliant products

4. Multi-product memory for easy switching between different packaging sizes

5. Data logging to ensure compliance and traceability

6. High-sensitivity detection captures even the smallest metal particles

7. Automatic rejection mechanism prevents contaminated products from reaching customers

8. Easy calibration and setup for a variety of product types

9. Hygienic stainless steel construction ensures safe food and pharmaceutical production

10. Seamless integration with existing conveyor and packaging systems

11. Compact, space-saving design for tight production lines

12. Real-time monitoring and alerts for weight deviation or metal detection

13. Flexible setup for a variety of product specifications and sizes

14. Durable IP65-rated stainless steel construction for use in harsh industrial environments

15. Enhanced data connectivity for reporting and analysis

Intelligent Checkweigher and Metal Detector Combo for Production Lines Solution

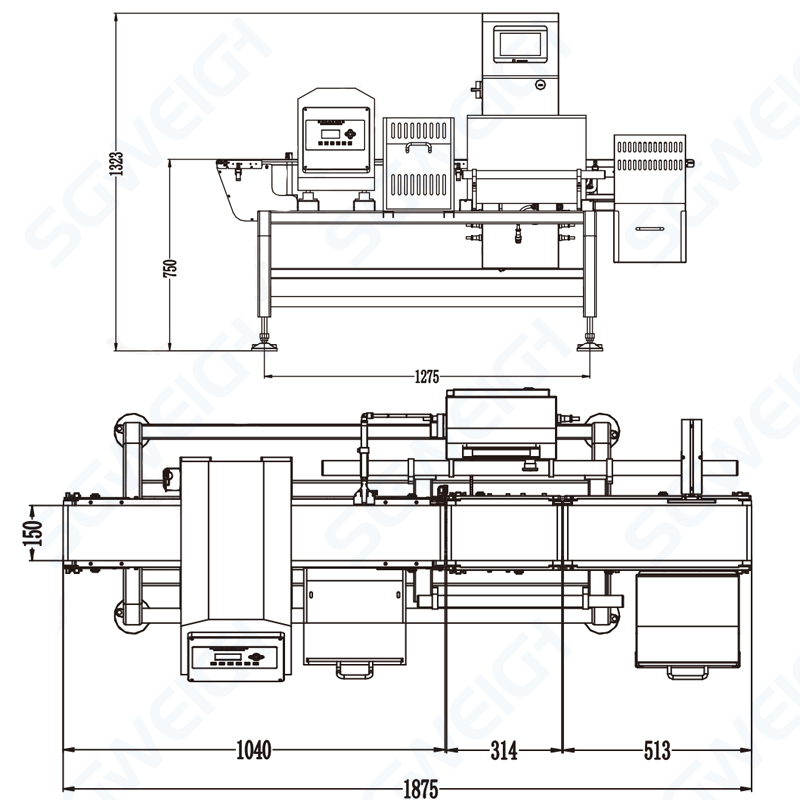

Model SG-JS150

Specifications 4010

Detection of hole width detection 150mm

Inspection hole height 100-200mm

Detection sensitivity

In empty state:(H)100mm ;Fe≥Φ0.8mm,SUS≥Φ1.2mm

(H)120mm ;Fe≥Φ1.0mm,SUS≥Φ1.8mm

(H)150mm ;Fe≥Φ1.2mm,SUS≥Φ2.0mm

(H)200mm ;Fe≥Φ1.5mm,SUS≥Φ2.5mm

Effective hole width detection 150mm

Effective hole detection level 100-200m

Weighing accuracy ±0.1g(Depend on product)

Conveyor height 750mm(±50mm)

Transmission capacity 10kg/times

Transfer direction From left to right

Conveyor belt max speed 25m/min

Material for conveyor belt Food grade PU belt

Capable of detecting ferrous, non-ferrous and stainless steel contaminants while verifying product weight in real time, the intelligent checkweigher and metal detector combination is ideal for the food, pharmaceutical, chemical and cosmetics industries.

SGWEIGH has extensive intelligent checkweigher and metal detector combo manufacturing experience, expertise, resources, and capabilities. Based on customer requirements, we can tailor-make an efficient, economical, and high-quality checkweigher and metal detector solution that meets customer needs.

Intelligent Checkweigher and Metal Detector Combo for Production Lines Solution

Delivery Date: After receiving payment, delivery will be within 15-30 working days.

Packaging: Protective film + wooden case

Logistics: Air, sea, or express (DHL, etc.)

Freight: The cost of shipping depends on the destination, mode of transport, and weight of the goods.

Payment: T/T, Western Union, PayPal

1. Seven-day replacement, one-year warranty, and lifetime maintenance. Before each sale, we rigorously inspect each product to ensure it is free of quality issues.

2. All products provided to customers are genuine and come with original parts.

3. During the warranty period, we will repair any parts damaged due to quality issues. For parts damaged outside the warranty period, we will only charge the cost of the parts we provide. If the equipment is damaged due to human error, we will repair or provide the parts at cost.

Related Products

4 Lane Sachet Liquid Packing Machine

Capsule and Tablet Random Inspection Checkweigher

Industrial Turntable Checkweigher for Bottling Line

Automatic Metal Detector for Capsules and Tablets

Precision Capsule Checkweigher for Pharmaceutical

Precision Carton Dynamic Checkweigher

Multi-Lane Packaging Machine for Liquid Stick Pouches

Precision 4-Lane Stick Weighing Checkweigher

Low-Cost Checkweigher for Food Industry

Multi-Conveyor Line Checkweigher for Honey

Hot Labels: intelligent,checkweigher and metal detector combo,production lines,solution,quote,price,manufacturer,supplier,factory