Real-Time Bottle Weight Inspection System Industrial Automatic Checkweigher Machine

The automatic bottle checkweigher is a high-precision system designed for fast-moving bottling lines, ensuring that every bottle meets precise specifications and rejects underfilled or overweight products in real time. Designed with ease of use in mind, this real-time bottle weight inspection system features a user-friendly touchscreen interface for quick product setup and seamless integration with existing conveyors. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Automatic bottle checkweigher pictures

1. Large screen display, clear and intuitive, easy to operate

2. Chinese and English interface (customizable in multiple languages)

3. Photoelectric positioning, turntable accurately delivers products to weighing sensor

4. Chain conveyor is sturdy and durable

5. Three-level operation authority management, support self-set password

6. Can store 100 types of data, powerful data statistics function

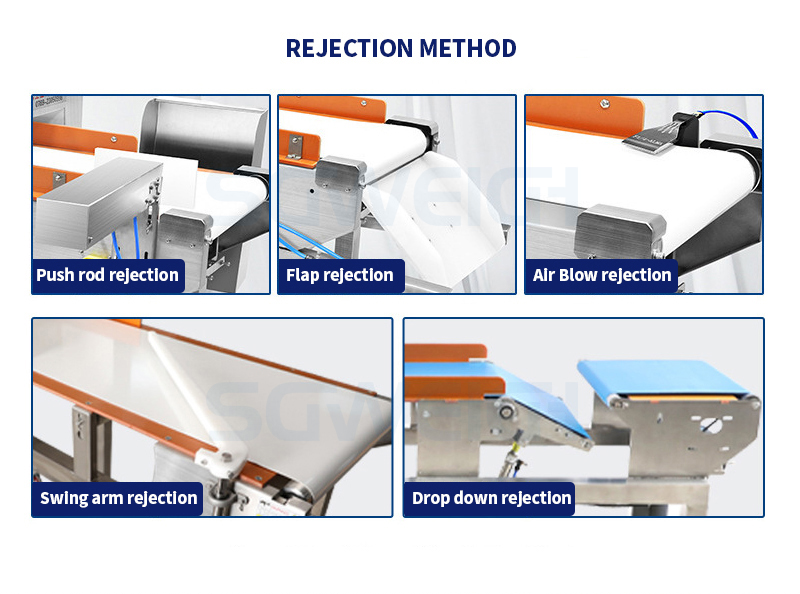

7. Automatic rejection of unqualified products (push-in and blow-in optional)

Automatic bottle checkweighers are widely used in pharmaceuticals, food, beverages, daily chemicals, light industry, electronics, hardware, industrial products, Chinese medicinal materials, aquatic products, poultry, fruits and vegetables, logistics and many other industries

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width p220mm

Machine Weight 85kg

Power Supply AC-220V 50HZ

Power 200W

Main Material SU304 stainless steel

To ensure that we will provide the right and qualified automatic bottle checkweigher, please let us know more details about your project, such as material, weight range, speed, bag size, etc. We will be happy to help you find the best checkweigher.

Real-Time Bottle Weight Inspection System Industrial Automatic Checkweigher Machine

Real-Time Bottle Weight Inspection System Industrial Automatic Checkweigher Machine

Payment method: T/T, L/C, Western Union, PayPal, credit card, trade guarantee

Packing: export standard wooden boxes and cartons, honeycomb cardboard boxes

Delivery time: 1-30 days after payment

Transportation: sea, air, express (DHL, FEDEX, TNT, 4PX, ARAMEX, EMS, etc.)

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service goal: service quality to win customer satisfaction

3. Service efficiency: If the equipment fails within the warranty period or outside the warranty period, our company will arrange maintenance personnel to perform maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: The product warranty period is one year. During the warranty period, our company will repair the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, only the cost will be charged for the accessories provided. If it is due to human factors The equipment damage caused by our company, the accessories repaired or provided by our company are calculated at the cost price.

Related Products

Dual-Conveyor Line Checkweigher For Stick Pouch

Liquid Multi-Lane Packaging Machine

High-Speed Capsule Checkweigher for Batch Inspection

High-Capacity Box Checkweigher for Industrial

High-Sensitivity Metal Detector for Food Processing

Pharmaceutical Rotary Checkweigher For Bottle

Small Sachet Multi-Lane Checkweigher

High-Precision Assembly Line Checkweigher

High-Sensitivity Metal Detector For Capsule Tablet

Industrial Multi-Lane Sachet Packing Machine

Hot Labels: real-time,bottle,weight inspection system,industrial,automatic,checkweigher machine,manufacturer,supplier,factory,price