Sugar Candy Checkweigher Inspection System Digital Conveyor Belt Checkweigher

This high speed sugar candy checkweigher system ensures that every product meets precise weight specifications. The fast-responding weighing sensor and intelligent feedback mechanism can reduce product waste, prevent underweight packaging, and enhance quality control of high-speed production lines. The integrated rejection system of the digital conveyor belt checkweigher can safely reject non-compliant products while keeping the production line running efficiently. Quick-release belts and easy-access panels can be easily cleaned and maintained, reducing downtime. You are welcome to contact us at any time for quotation.

High speed sugar candy checkweigher system pictures

Type SG-150H

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 90 m/min

Max Speed 250 pcs/min

Belt Width 150mm

Machine Weight 70kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Sugar Candy Checkweigher Inspection System Digital Conveyor Belt Checkweigher

1. Easy-to-use backlit screen with menu-based navigation for ease of use.

2. Password protected main menu.

3. Stores up to 100 different product settings for easy setup and quick switching.

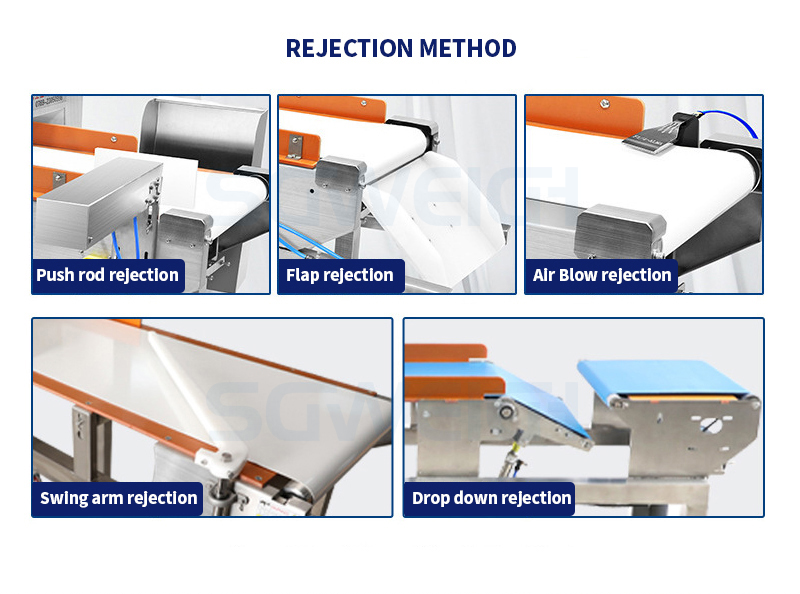

4. Equipped with automatic product rejection.

5. Rejected products can be further classified as below average or above average weight.

6. Sturdy stainless steel chassis for durability and corrosion resistance.

7. Prevents product leaks and consumer complaints related to missing items or underweight packages.

8. Powered conveyor: passes all products through the weighing scale, ensuring no product is unchecked.

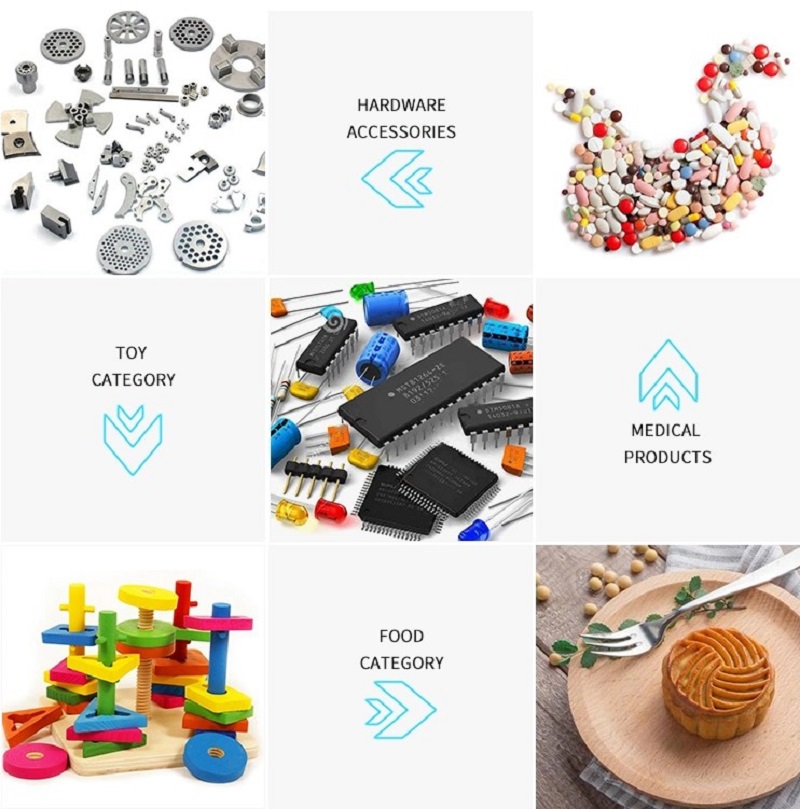

1. Leisure food: various packaging such as potato chips, biscuits, jellies, sweets, tea bags, instant noodles, etc.

2. Agricultural products: rice bags, dried fruit net bags, grains, frozen products

3. Daily cosmetics: bottled shampoo, cosmetic bags, filling aerosols

4. Hardware industry products: printing, toys, PCB boards, metal parts

5. Pharmaceutical industry: bottle pills, small particle sachets, pulse bottles, etc.

Most of our high speed sugar candy checkweigher systems are custom made to specific project requirements.

If possible, please let us know more details about your project, such as material, weight range, speed, bag size, etc.

Contact us before ordering.

Sugar Candy Checkweigher Inspection System Digital Conveyor Belt Checkweigher

The whole machine is packed in two layers.

The pre-packaging uses plastic bags to deliver the whole machine, and the key parts are protected by foam plastic.

The engineering packaging uses a sturdy polyethylene wooden box that meets the import standards of different countries.

1. It can provide you with manuals/videos for machine installation, adjustment, setup, and maintenance.

2. If any problems occur and you cannot find a solution, telecommunications or online 24 hour face-to-face communication.".

3. If you agree to pay the fee, engineers and technicians can be dispatched to your country/region to provide services.".

4. The machine has a one-year warranty period

5. Shanghai Shigan has an independent after-sales service team. If there is an emergency, please call the sales personnel or our After Sales Manager.

Related Products

Strip Bar Packaging Multi-Lane Packing Machine

4-Line Bar Packge Checkweigher With Rejector

Automatic Checkweigher For Tablet Weight Sampling

Super High-Speed Box Checkweigher Solution

High-Precision #00 #01 Capsule Checkweigher

High-Speed Checkweighing for Cosmetics Industry

Automatic Rotary Checkweigher For Bottle Industrial

Vertical Metal Detector For Capsule Manufacturing

Sauce Pouch Multi-Lane Packaging Machine

Compact Food Package Metal Detection Machine

Hot Labels: sugar,candy,checkweigher,inspection system,digital,conveyor,belt,check weigher,manufacturer,price,supply