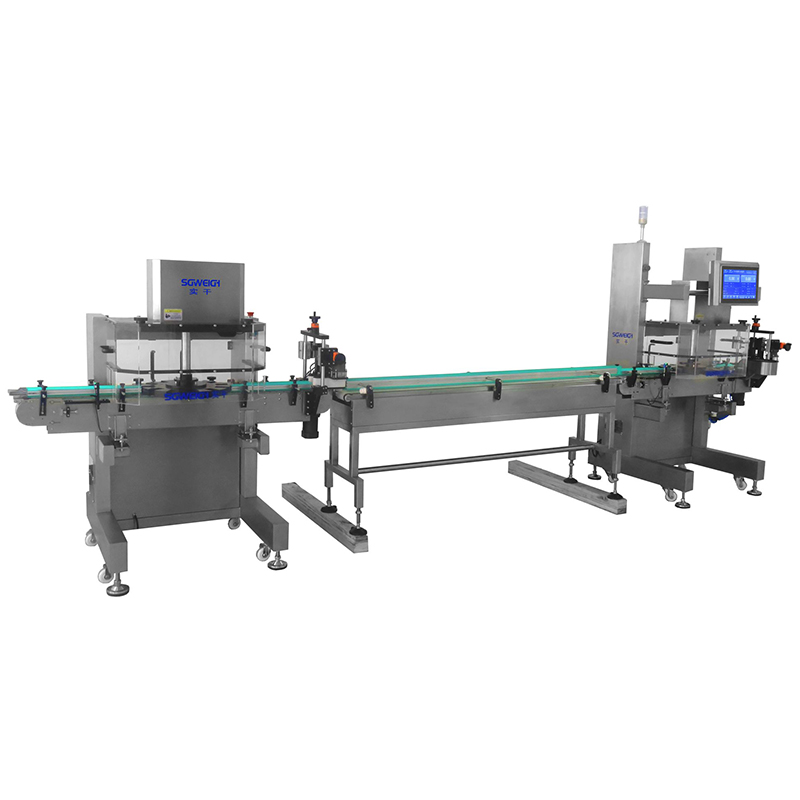

Vials Jars Bottles Inline Rotary Checkweigher Filling Line Weight Control

This vials jars bottles rotary checkweigher is designed for superior weighing accuracy and optimized for vials, cans, and bottles of various shapes and sizes. Advanced load cell technology and stable rotary motion provide consistent and repeatable weight verification, even for lightweight or high-value products. Designed for continuous operation, the rotating structure of high speed rotary checlweigher enables smooth container handling and high throughput, eliminating errors caused by vibration. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us for a quote.

Vials jars bottle rotary checkweigher pictures

Type SG-Z

Weighing Range 2-300

Restrictions of Products:φ10-100 H:20-200mm

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min,120 pcs/min,180 pcs/min(optinal)

Belt Width 100mm

Machine Weight 260kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

1. Gentle rotary handling prevents bottles from tipping over or breaking.

2. High throughput to meet ever-increasing production demands.

3. Real-time weight analysis automatically filters out underfilled or overfilled products; an automatic rejection system ensures only qualified bottles pass through.

4. Sanitary stainless steel construction with a small footprint.

5. User-friendly touch interface for quick setup and adjustments.

6. Data logging function for continuous quality auditing.

7. Long-term stable operation with minimal maintenance.

Vials jars bottles rotary checkweigher supports various sizes of glass, PET, and plastic bottles, widely used in food, pharmaceutical, packaging, and agricultural product processing industries.

Vials Jars Bottles Inline Rotary Checkweigher Filling Line Weight Control

The high speed bottles rotary checkweighers shown may not meet your requirements. We have professional technicians who can provide professional customized solutions based on the user's product characteristics and application scenarios.

Vials Jars Bottles Inline Rotary Checkweigher Filling Line Weight Control

1. Packaging Materials: Typically, international standard export packaging boxes are used, offering excellent wear resistance, shock absorption, and waterproofing. Box materials can include hardwood boxes, plastic boxes, or export-specific cardboard boxes.

2. Protective Measures: To ensure the machine is protected from damage during transportation, sufficient filler materials, such as foam and shock-absorbing cotton, need to be added inside the packaging box.

1. Training services:

We will train your engineer to install our weigher. You can send your engineer to our factory or we dispatch our engineer to your company. We will introduce your engineer how to install the weigher and how to fix problem.

2. Trouble shooting service:

Some times if you can not fix the problem in you contry,we will seed our engineer there if you need us to support.Of course,you need to afford the round trip flight Ticket and accommodation fee.

3. Spare parts replacement:

For spare parts support: If a spare part breaks during the guarantee period, we will send it free of charge and pay the express delivery fee. If the spare part breaks, please send it back to us at cost.

Related Products

Water Multi Lane Sachet Packing Machine

Dynamic Cosmetic Industry Metal Detector

Multi-Lane Checkweigher for Pharmaceutical

Online Weight Checker for Beverage Cans

Capsule Tablet Checkweigher for Small Batch

Combined Metal Detector with Check Weigher System

100% Inline Weight Control Multi-Lane Checkweigher

Food Metal Detector for Beverage Filling Line

Multi-Lane Packaging Machine for Food Sauces

Ultra-High-Speed Checkweigher for Small Box Bottle

Hot Labels: vials, jars, bottles, inline rotary checkweigher, filling line, weight control, quote, manufacturer, supplier, factory, price