300g Digital Dynamic Glass Bottle Check Weighing Scale Clamping Conveying Electronic Checkweigher

Product Description

The glass bottle check weighing scale can screen products of different weights alone or can be used together with other automatic assembly line equipment to realize real-time online weighing, and screen and distinguish customer OK and NG products, with a weighing accuracy of ±0.2g, depending on the specific product. The automatic checkweigher can be customized according to customer needs, and the accuracy of some products can reach 0.02g.Any OEM and customer design orders are welcome! If you are interested in our products, please contact us.

Specification Parameter

TypeSG-150

Weighing Range3-500g

Limited of productL: 200 W:150 H: 3-200mm

Accuracy±0.1g Depends on product

Division Scale0.1g

Belt Speed0- 65 m/min

Max Speed150 pcs/min

Belt Width150mm

Machine Weight60kg

Power SupplyAC 110/220V ±10% 50HZ

Power100W

Main MaterialSU304 stainless steel

Automatic Checkweigher Workflow

The product is transported to the "automatic checkweigher" after passing through the previous assembly line or manual feeding.

1. The product enters the "acceleration section" of the dynamic check weigher machine: the distance between the products will be pulled apart to ensure that when entering the "weighing section", it is a single product instead of multiple products. When the product ordering is irregular, it can also be organized by the "acceleration section".

2. The product enters the "weighing section" of the digital check weigher: the weighing system quickly detects the weight of the product; and immediately judges whether the product weight is within the target weight range. If the weight of the product is qualified, the checkweigher will be sent out without error; if the weight of the product is unqualified, a rejection delay signal will be given. At the same time, the system will automatically record the number of qualified and unqualified products.

3. The product enters the "rejection section" of the electronic check weigher machine : when the rejection section detects the rejection delay signal, it will make a timely rejection action to accurately reject the unqualified products.

300g Digital Dynamic Glass Bottle Check Weighing Scale Clamping Conveying Electronic Checkweigher

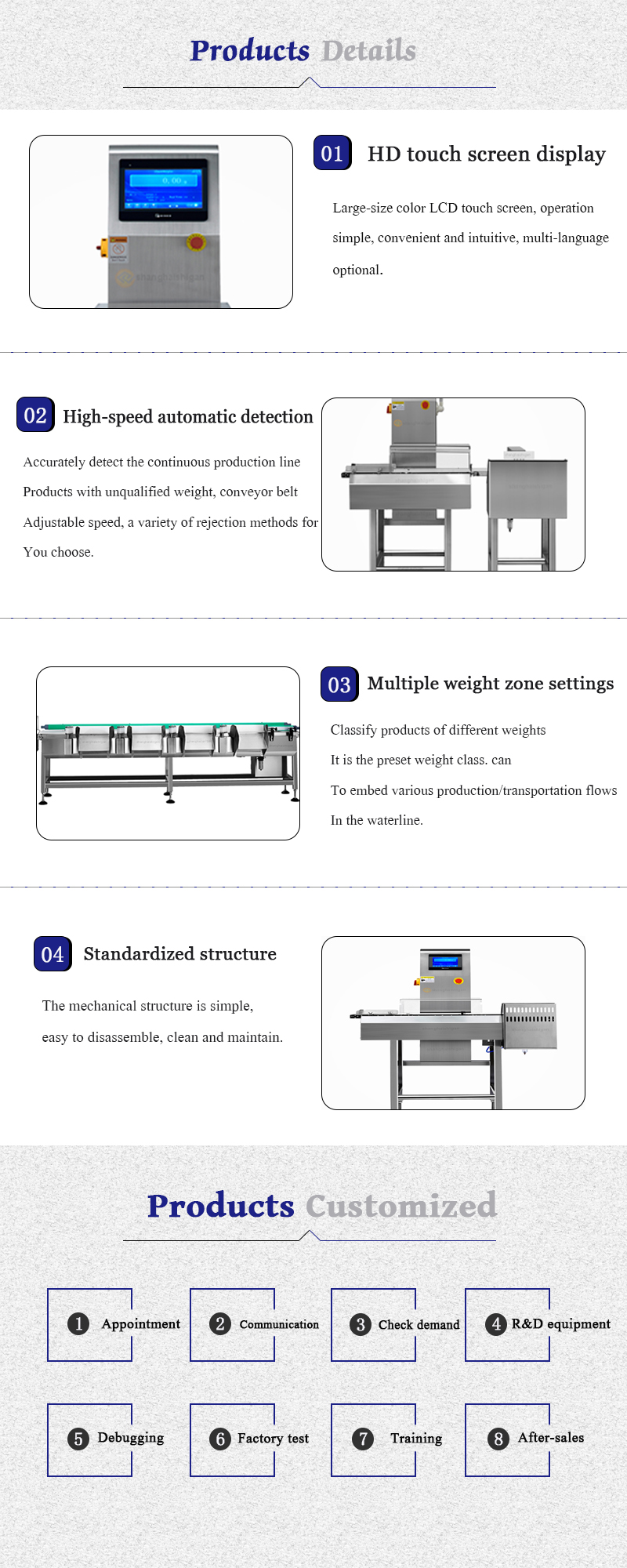

Automatic check weigher machine details

Main Advantages of Bottle Check Weigher Scale

1. Large-size color LCD touch screen interface, simple operation and intuitive display.

2. Support multiple languages: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (customer specified), the default is Chinese and English.

3. It can store 200 kinds of product testing data, which is convenient for users to call.

4. USB data storage interface, which can transfer report data to PC for analysis and printing.

5. The parameter setting is password protected, only the management personnel operate.

6. Automatic zero tracking system to ensure reliable detection data.

7. Built-in temperature and noise compensation system to ensure system stability.

8. Online printing function (customized to be customized).

9. Data external communication interface, which can be connected to other equipment in the production line (eg: labeling machine and inkjet printer) (customized).

10. A variety of rejection devices: lever type, air blowing type, roller push rod type, belt push rod type, drop type, flap type, belt retraction type.

11. The mechanical structure is simple, which is convenient for disassembly, cleaning and maintenance.

Packaging & Shipping

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 20 days after payment

300g Digital Dynamic Glass Bottle Check Weighing Scale Clamping Conveying Electronic Checkweigher

About Our Company

After Sale Serives

Over the years, Shanghai Shigan Industrial Co,.Ltd has been serving customers in various industries and has concluded a complete product service guarantee system through research and exploration, providing users with high-quality and timely pre-sale, in-sale and after-sale services:

1. Quality Assurance

Shanghai Shigan Industrial Co,.Ltd guarantees that the electronic check weighing scales provided to customers are produced by the original factory, and the factory data and accessories are complete. In order to maintain the normal operation and maintenance of the contract equipment, our company guarantees that the technical products provided are complete, clear and correct.

2. Quality assurance measures

Warranty Period: On-site service is provided during the warranty period.

(1). The company has an after-sales service center, which is mainly responsible for after-sales service and technical consultation. It is guaranteed that engineers are always available to provide various technical services.

(2). Vulnerable parts: the company spares the stock of various commonly used parts to ensure that the problem can be solved in a short time.

Related Products

Electronic Aluminum Parts Check Weighing Machine

Conveying Sorter Snack Checkweighing Machine

Vegetable Fish Checkweigher And Metal Detector Combo

Slope Type OEM/ODM Industrial Metal Detector

Bottled Medicine Digital Metal Detector

High Precision Metal Detection Machine Price

Hot Labels:300g,digital,dynamic,glass,bottle,check weighing scale,clamping,conveying,electronic,checkweigher