Full-automatic Product Line Weigher Bagger Machine Conveyor Belt Inspection Tray Check Weigher Machine With Rejector

Shanghai Shigan's independent and innovative online weighing control software integrates the full-automatic check weigher into the existing production line, which can not only accurately identify and eliminate unqualified products, but also identify the links where errors occur and give an alarm in time, so as to reduce the product rejection rate from the root cause and avoid product waste. The weight range of the conveyor belt checkweigher with rejector can be set freely. This automatic belt weight sorting scale has various production inspection data report functions, and supports data export and network communication. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

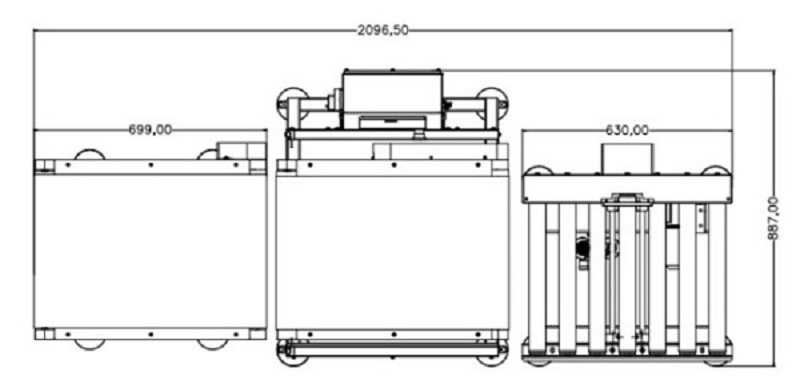

Full-automatic check weigher system pictures

1) High efficiency and economy: multi-stage sorting and automatic weighing replace manual work to improve efficiency;

2) Strong universality: the standardized structure and standardized human-computer interface of the whole machine can complete the weighing of various materials

3) Multi level expansion: 2-12 levels of sorting can be customized according to customer requirements;

4) Clear and sensitive: imported high-definition color touch screen, a variety of voice images, information at a glance;

5) Professional and easy to use: professional weighing scale system, with rich functions, simple operation, and various statistical formats of weighing data, meets the needs of various production data;

6) Extensive expansion: a variety of sorting methods are available, and various expansion equipment can be installed according to customer needs;

7) Convenient maintenance: fast detachable structure design, convenient cleaning and maintenance;

8) Beautiful and durable: 304 stainless steel, or high-strength aviation aluminum body; Ensure the stability of long-term operation.

Full-automatic Product Line Weigher Bagger Machine Conveyor Belt Inspection Tray Check Weigher Machine With Rejector

Type SG-450

Weighing Range 0.05-20/30kg

Limited of product L: 500 W:450 H: 3-400mm

Accuracy ±1g

Division Scale 0.1g

Belt Speed 0- 40 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 100kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Parameters are standard models, can be customized according to requirements

1. The properties of the tested product are also different from the use environment, and the actual detection speed and accuracy are slightly different

2. The displayed machines are standard specifications, and other sizes and special requirements can be customized

3. Multiple removal methods are optional and can remove overweight or insufficient products.

The full-automatic check weigher is widely used in food, chemical industry, logistics, aviation, medicine, paper making, building materials, batteries and many other industries and fields.

1. Under weight detection and overweight detection of packaged products; Detection of missing accessories in the package, such as instructions, accessories, gifts, desiccants and other accessories.

2. Full container detection: lack of parts detection, lack of package detection, lack of box detection, lack of bottle detection, lack of tank detection, lack of bag detection, etc.

3. USB data storage interface can transfer report data to PC for analysis and printing; Password protection is set for parameters, and only management personnel can operate.

1. Before packaged, the machines will be tested strictly to guarantee the stability and high accuracy.

2. After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Full-automatic Product Line Weigher Bagger Machine Conveyor Belt Inspection Tray Check Weigher Machine With Rejector

Our manufacturer has ISO9001, CE international certification,

1. More than 11 years of production experience

2. More than 10 years of foreign trade experience

3. More than 10 national technology patents

4. Cumulative overseas sales exceed 1,000 sets

5. Comply with EN60204 international standard

Pre-sales advice

We will help you customize a suitable weighing and packaging solution according to your requirements and specific circumstances.

Maintenance service

Shanghai Shigan provides long-term maintenance services, free of charge any maintenance parts during the warranty period, and charges fees only after the warranty expires.

Employee training

Shanghai Shigan provides our customers with free technical training to fully grasp the correct product maintenance technology.

Customer service

Shanghai Shigan designs customized production lines for customers based on actual requirements and other factors.

Related Products

Liquid Metal Detector For Cosmetic Industry

Manual Missing Inspection Weight Checking Machine

Textile Industry Weighing Metal Detection Machine Price

Conveyor Belt Metal Detector Sensitivity Food Industry

Loose Product Inspection Check Weigher System

Belt Metal Detector With LCD Screen French Price

Hot Labels:full-automatic,product line,weigher bagger machine,conveyor belt,inspection,tray,check weigher machine,checkweigher with rejector,checkweigher,price