Granular Weighing Capsule Checkweigher High Precision Pharmaceutical Tablet Online Customized Check Weigher Factory

High precision checkweigher as known as check weigher, inline check weighing machine, weight checker, weight detection machine, weight sorting machine, sorting machine, weight check machine and etc,.

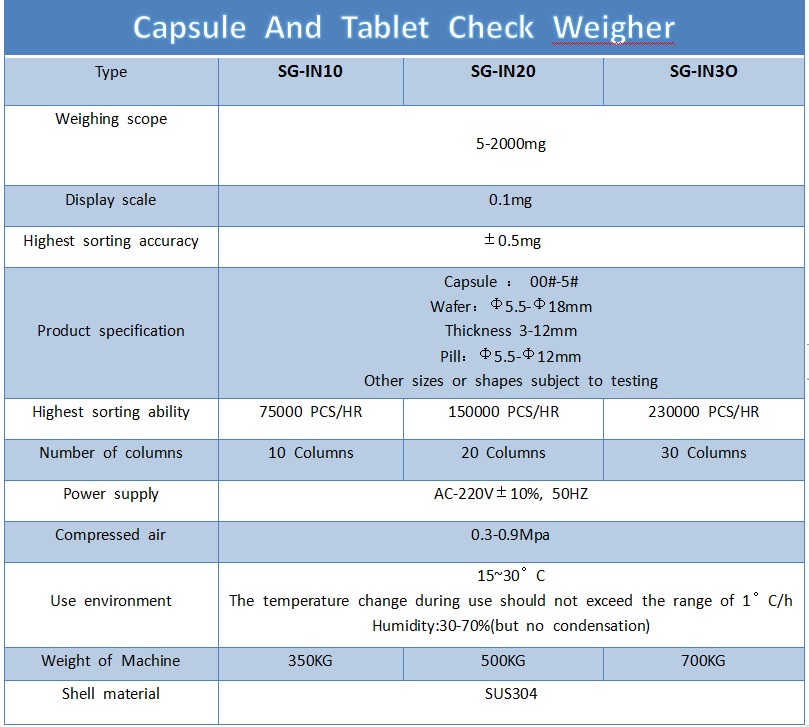

This granular weighing capsule checkweigher adopts an innovative "unit expansion structure" and an "infinite parallel" working mode, which can infinitely improve the detection efficiency. It can weigh and inspect all capsules and tablets of different quantity levels, quickly eliminating unqualified products. The high precision pharmaceutical checkweigher has become a necessary equipment in multiple industries. It is a high-tech new product that integrates transportation, weighing, measurement, and control. For further information about our services, please contact us.

Granular weighing capsule checkweigher pictures

1. The core part of the equipment adopts high-precision electromagnetic balance weighing sensors and DSP high-speed signal processing systems to measure data quickly, operate stably, and have strong resistance to environmental interference;

2. Granular weighing capsule checkweigher can detect all types of capsules such as 000 000 0 1 2 3 4 5 SA and SB, as well as conventional tablets;

3. The standardized design of the mold has high flexibility, strong interchangeability, simple installation, and can be quickly disassembled and positioned without errors;

4. Reasonable design, minimal equipment failure points, convenient use, simple operation and maintenance, and low maintenance costs in the later stage;

5. The human-machine interface synchronously displays the weight value of each channel, and visually displays the qualification of the current channel product in the form of a green and red histogram. The device synchronously lights up the indicator light, making the detection process more intuitive;

6. The innovative design of three channels for good products, defective products, and unchecked products solves the problem of discharge of unchecked products during abnormal shutdowns and misjudgment;

7. Equipment failure automatic alarm, prompt alarm information;

8. Comply with 21CFR part11, three-level password, electronic record and electronic signature to ensure Data integrity and facilitate audit tracking;

9. Rich peripheral interfaces, Ethernet, USB, COM ports, wireless WiFi, facilitate remote monitoring and networked data exchange.

Granular Weighing Capsule Checkweigher High Precision Pharmaceutical Tablet Online Customized Check Weigher Factory

How to choose a weighing scale?

-Confirm project requirements, such as product size, weight, accuracy, and expected speed.

-Ensure that the rack is stable and free from vibration during standstill or operation.

-Exquisite workmanship.

-The components have good quality and long-term reliable performance.

-Easy to operate and use

We can design the most suitable weighing scale scheme for your production line to meet the different needs of various complex production lines.

1. Granular weighing capsule checkweigher can achieve online weighing of products in dynamic operation

2. Dynamic weighing detection can be carried out according to preset weight requirements

3. Can automatically detect the weight of each product at 100%

4. Depending on the speed of the assembly line. Standardized weight testing and troubleshooting of quality inspection weight parameters

5. Automatically eliminate products with substandard weight or perform quality classification

Granular Weighing Capsule Checkweigher High Precision Pharmaceutical Tablet Online Customized Check Weigher Factory

Shanghai Shigan Industrial Co., Ltd. is a high-tech and innovative enterprise specializing in the research and development, production, and sales of electronic weighing instruments.

Our company has a high-quality R&D and sales team for weighing instruments, relying on deep technological accumulation and extensive market demand. With scientific and rigorous design, management, and manufacturing processes, we provide customers with high-quality weighing products with stable performance, practicality, convenience, aesthetics, and excellent prices, as well as comprehensive weighing solutions

Our main products include: digital metal detector,conveyor belt metal detector,automatic checkweigher metal dtector, checkweigher, high-speed and high-precision checkweigher and a series of assembly line equipment.

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

Pre sales service

Before providing suggestions to customers, we will clearly confirm their requirements to ensure that the suggestions we provide meet your requirements. Then we will give you a good quote.

On sale services

After placing an order with our production department, we will follow your order well and inform you of the production status. We will provide you with photos

After-sale service

The warranty period for this machine is one year, calculated from the date the customer receives the machine. During the warranty period, we will replace damaged parts (excluding human damage).

Related Products

Wide Range Tunnel Weighing Metal Detection Machine Factory

Small Packaging Efficient Weight Checker

Bagged Boxed Dried Fruit Food Metal Detector

4 Lines Multi-line Small Bag Check Weigher

Food High-speed Weight Checker Check Weighing Machine

Chips Conveyor Metal Detector for Food Processing

Hot Labels: granular weighing,capsule checkweigher,high precision,pharmaceutical,tablet,online,customized,check weigher,supplier,manufacturer,factory,price