Digital Food Industry Metal Detector Production Line Metal Detection Machine

Food Industry metal detectors are high powered machines used to inspect large quantities of food on conveyor belts. They are highly sensitive and stable to ferrous, non-ferrous and stainless steel. Digital food production metal detection machine are primarily used for in-line inspection of finished and semi-finished products, providing final inspection before shipment, and are very important in ensuring the safety of the final product by detecting and rejecting any metal contaminants that may be present. To know more about us, please you do not hesitate to contact us or visit our factory.

Food Industry metal detector photos

Standard machine (height × width): 100mm × 600mm (new machine products have changed, everything is subject to the actual product)

External dimensions (length × height × width mm): 1700 × 950 × 1100

Detection window width: 600mm; height: 100mm-120mm-150mm-200mm (optional)

Sensitivity: φ0.8-1.0-1.2-1.5mm iron ball

Alarm method: sound and light alarm, and automatic shutdown and return

Power supply: 220V 50Hz

Power: 60W

Weight: 220kg

Digital Food Industry Metal Detector Production Line Metal Detection Machine

Food Industry metal detector manufacturers offer a wide range of customization options to tailor the design, functionality and specifications of a digital metal detector system to meet the specific needs and requirements of OEM/ODM customers.

Customization options may include conveyor configuration, reject mechanisms, weighing capabilities, software functionality, user interface and integration capabilities.

1. Stable high detection accuracy, mature digital phase modulation technology, effectively suppress product effects, so that the system has stable high detection accuracy;

2. Automatic setting function, parameter setting is simple and fast, the system can automatically analyze product characteristics and calculate appropriate detection parameters;

3. User level management function, set passwords suitable for different user levels for different positions, clarify permissions and responsibilities, and facilitate management;

4. Database function, product database, automatic counting library, detection information record library, can quickly realize product switching and historical data review;

5. Humanized design, equipped with intelligent operating system, 7-inch LCD color touch screen, simple screen, simple and intuitive operation, can easily realize human-computer dialogue;

6. Printer interface, the system has a printer interface, which can print detection information in real time through the printer, and the data viewing is intuitive and clear;

7. Support built-in large-capacity SD card to save more data (including detection record data, product configuration data, etc.) to meet large data volume requirements (optional);

8. Support data export function through USB flash drive.

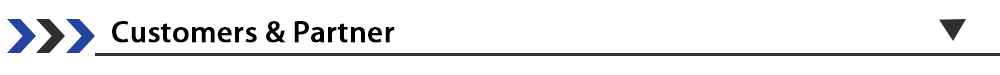

Food Industry metal detectors are widely used in a full range of applications such as food, pharmaceuticals, textiles, toys, chemicals, cosmetics, raw materials, etc. Different machine types (conveyor type, free fall type, pipeline type, pharmaceutical type, etc.) can meet complete detection requirements.

Digital Food Industry Metal Detector Production Line Metal Detection Machine

- Fumigation certification for wooden packaging for overseas shipments

- Inner plastic film wrapping to protect goods from salt, wind or damage

- Shipping terms: EXWORK, FOB, C&F, CIF by sea or air

1. Product quality commitment:

(1). The manufacturing and testing of products have quality records and testing data.

(2). For the inspection of product performance, we sincerely invite users to personally visit the entire product process and performance inspection. Only after confirming that the product is qualified can it be packaged and shipped.

2. Product price commitment:

(1). Under the same competitive conditions, our company sincerely provides you with preferential prices without reducing the technical performance of the product or changing the product components.

3. Delivery time commitment:

(1). Product delivery time: as far as possible according to user requirements. If there are special requirements, they must be completed in advance to strive to meet user needs.

Related Products

High Sensitivity Pharmaceutical Metal Detector

Online Capsule Tablet Checkweigher

Aluminium Foil Stick Sachet Multi-lane Packing Machine

Small Box Sachet Mini Checkweigher

High Performance Capsule Tablet Sampling Checkweigher

Automatic Balance Grade Check Weigher For Packing Line

Checkweigher And Metal Detector Combination

Pharmaceutical Metal Detector for Capsule Tablet

Food Checkweigher For Plasic Bottle

Large Carton Box Checkweigher Machine for Industrial

Hot Labels: digital,food industry,metal detector,production line,metal detection machine,supplier,manufacturer,factory,price