Industrial High Speed Automatic Conveyor Control Check Weigher Weiging Scale

Product Description

The high speed check weigher produced and sold in Shanghai Shigan is an online weight detection equipment specially designed for the full-automatic packaging line. Automatic conveyor checkweigher system is widely used in many industries and is suitable for the weight detection of packaging products. High speed and high precision checkweigher can automatically eliminate overweight and underweight products and ensure the quality up to standard.Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Specification Parameter

TypeSG-220

Weighing Range5-1500g

Limited of productL: 300 W:220 H: 3-200mm

Accuracy±0.2g Depends on product

Division Scale0.1g

Belt Speed0- 60 m/min

Max Speed100 pcs/min

Belt Width220mm

Machine Weight60kg+44kg

Power SupplyAC 110/220V ±10% 50HZ

Power100W

Main MaterialSU304 stainless steel

Main Advantages

1. Weighing and sorting technology: domestic sorting accuracy ± 0.05g, sorting speed 300 times / min.

2. Accurate product sorting function: automatic analysis of digital weighing unit and zero point, providing production trend feedback signal, adjusting the packaging accuracy of upstream packaging machine and reducing cost.

3. Powerful data tracing function: query and print unqualified products. Statistical charts such as histogram and output chart can be generated in the sorting process. The built-in data transmission system is convenient for production control.

4. Domestic market share: regardless of the industry application scope or customer group, Dongguan Shanan has always maintained the industry and has comprehensive application experience and technology accumulation.

5. Comprehensive operation yield: flexibility of weighing, detection and sorting, stable operation, with power-off data storage and fault self-test alarm function.

6. Humanized design and easy operation: the 10 inch color touch screen operation interface can store 100 varieties in advance, and the sorting and switching is flexible, so as to realize the switching of products without shutdown; Modular design, the conveyor belt adopts buckle design, which is convenient for maintenance and cleaning.

7. The domestic shunt removal device prevents the product from falling down and spilling materials in the sorting process, and ensures the integrity of the tested objects.

8. In depth development, customization and supporting integration capability: it can meet the requirements of different products and environments, customize various applicable schemes, and connect metal detector, packaging machine and other equipment.

Industrial High Speed Automatic Conveyor Control Check Weigher Weiging Scale

Application

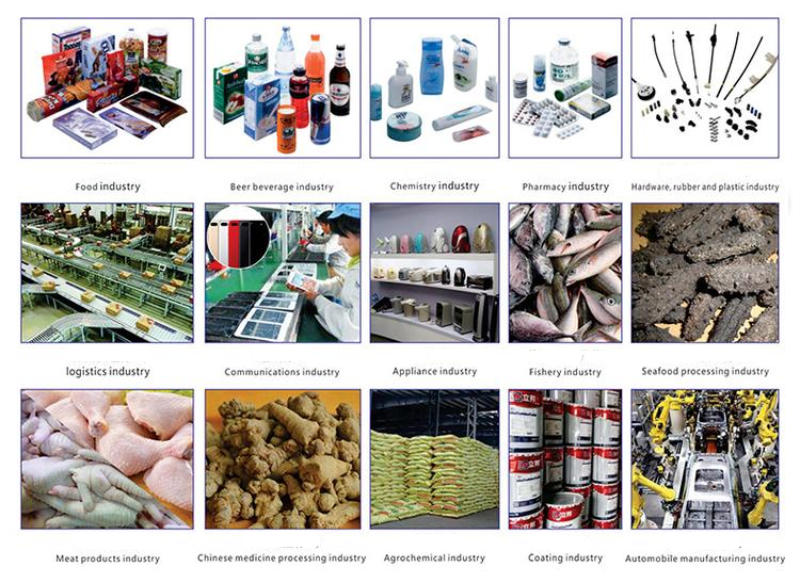

High Speed checkweigher is applicable to the detection of small packaging and lack of packaging in food, medicine, daily chemical, electronics, chemical, beer and beverage industries.

Automatically check whether the weight range of packaged finished products is qualified, and the sorting mechanism will remove the unqualified products.

Industrial High Speed Automatic Conveyor Control Check Weigher Weiging Scale

About Us

Introduction to our company

1. Established in 2010.

2. High tech enterprises in Shanghai.

3. Our company has more than 10 years of experience in the field of checking machinery and has its own factory, which can provide you with the most suitable projects for your needs.

4. 6-8 International Machinery exhibitions every year.

5. Supply OEM / ODM manufacturing.

6. Several engineers to ensure quality / service.

7. As a manufacturer and trader, we have good quality and price control over our products.

8. The products are exported to more than 40 countries such as the United States, Canada and Mexico; Australia, New Zealand; Saudi Arabia, Italy, Spain; France, Poland, Israel, Russia, South Korea; Thailand, Indonesia, Malaysia, Philippines, etc.

After Sale Service

1. Service tenet: fast, decisive, accurate, thoughtful and thorough

2. Service objective: service quality to win user satisfaction

3. Service efficiency: in case of equipment failure during or outside the warranty period, our company will arrange maintenance personnel to provide maintenance services for customers within 24 hours after receiving the notice.

4. Service principle: the warranty period of the product is one year. During the warranty period, our company will repair the damage of parts and components caused by quality reasons free of charge. For the damage of parts and components outside the warranty period, only the cost fee will be charged. If the equipment is damaged due to human factors, the parts repaired or provided by our company will be calculated at the cost price.

Related Products

3kg Coffee Beans Real-time Weighing Metal Detector

Professional Metal Detectors For Textile Industry

Liquid Water Metal Detection Machine Price

Bottled Medicine High-speed Metal Detector

Conveyor Belt Metal Detector With Reject

Three-Color Warning Light Checkweigher System

Hot Labels:check weigher,check weiging scale,industrial,high speed,automatic,conveyor,control