Sauce Pipeline Type Digital Metal Detection Machine High Quality Conveyor Belt Metal Detector For Food Industry Supply China

The metal detector for food industry is an intelligent detection machine developed using independent digital technology. This digital metal detection machine adopts the principle of balance and achieves full digitalization and intelligence of metal detection technology through the integration of DSP and microcontroller. The operation is highly intelligent, with excellent performance, simple and easy to use, and improves production efficiency. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Food metal detector photos

Model category: Standard model

Detection channel width (mm): 300-400 (customizable)

Detection channel height (mm): 100 (customizable)

Detection sensitivity: diameter of iron ball( φ Mm) 0.6-0.8; 304 stainless steel diameter( φ Mm) 1.2; Copper, aluminum, lead and other non-metals( φ Mm) 1.2

Alarm method: buzzer, LED sound and light alarm, and automatic shutdown

Machine material: 304 stainless steel

Machine size: 1520 * 860 * 930MM

Machine weight: approximately 200 kg

Power supply: AC220V 50-60Hz

Power: approximately 140W

Load capacity 5-25KG

Conveying speed: 24m/min (50Hz)

*The above technical indicators are the detection data of the belt surface test block when the machine is empty

*The detection sensitivity may vary slightly depending on the product and usage environment

*If there are special needs, they can be customized according to customer requirements.

1. The operating system adopts a humanized and intelligent design, with one click self-learning function;

2. The main control board of the probe adopts digital intelligent technology, with high sensitivity and strong anti-interference ability;

3. Adopting LCD display control, intelligent and user-friendly interface design, easy to operate and easy to learn;

4. Utilize phase adjustment technology to effectively suppress product effects;

5. Metal detector for food industry has multiple product parameter memory functions and can store detection parameters of different products;

6. Metal detector for food industry has the function of automatic fault detection and prompt upon startup, which can effectively eliminate invalid detection;

7. The entire machine adopts modular design and assembly, with simple assembly, debugging, and disassembly, and convenient maintenance;

8. Metal detector for food industry can be customized according to the size, weight, and product characteristics of the tested product;

9. Customization for waterproofing, dust prevention, vibration prevention, and explosion prevention can be carried out according to the environmental and safety needs of the production site;

1. Detect metal impurities in industries such as food, medicine, toys, shoe materials, textiles, daily chemical products, and chemical products to ensure that there is no metal pollution in the products and provide reliable quality assurance.

2. Detect metal impurities in raw materials in industries such as plastics, textiles, wood, and mining, protect critical equipment, reduce downtime, maintenance time, and costs, and improve work efficiency.

Sauce Pipeline Type Digital Metal Detection Machine High Quality Conveyor Belt Metal Detector For Food Industry Supply China

Shanghai Shigan Industrial Co., Ltd. has been engaged in the research and development, production, sales, and service of metal testing machine technology for over 11 years. Our goal is to help customers achieve automated production and management. We continuously provide effective solutions to customers to reduce costs and improve market competitiveness. It is widely used in fields such as snack food, puffed food, fresh frozen food, agriculture, medical, chemical, and hardware. We also export to overseas markets such as Malaysia, Vietnam, Indonesia, the Philippines, Kazakhstan, Uzbekistan, the United Arab Emirates, Saudi Arabia, and have received countless praise and trust!

Our main products are: digital metal detector,conveyor belt metal detector,automatic checkweigher metal dtector, checkweigher, high-speed and high-precision checkweigher and other series of assembly line detection equipment.

Sauce Pipeline Type Digital Metal Detection Machine High Quality Conveyor Belt Metal Detector For Food Industry Supply China

1. Waterproof PO film+wooden box

1) Dust removal and cleaning

2) Lubricating transmission components

3) Divide the machine into modules

4) Wrap the module in plastic film

5) Load the module into a plywood box

6) Mark the box with a shipping mark

2. According to the customer's packaging requirements.

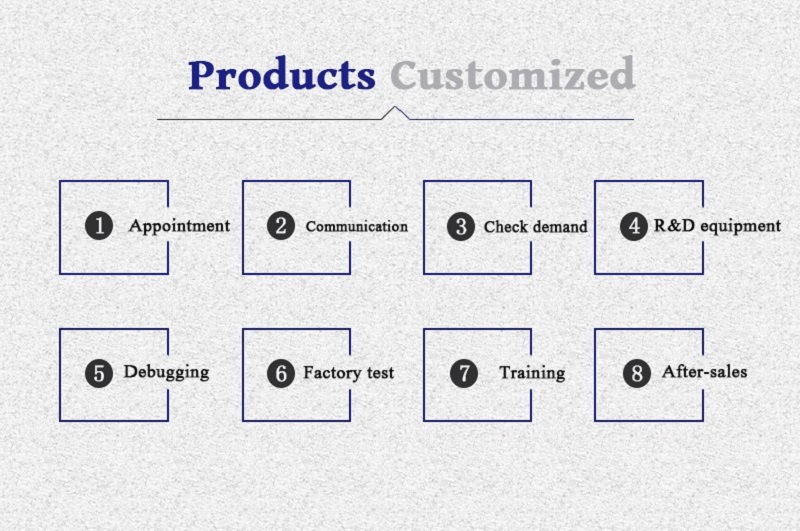

Pre sales service

Before providing suggestions to customers, we will clearly confirm their requirements to ensure that the suggestions we provide meet your requirements. Then we will give you a good quote.

On sale services

After placing an order with our production department, we will follow your order well and inform you of the production status. We will provide you with photos

After-sale service

The warranty period for this machine is one year, calculated from the date the customer receives the machine. During the warranty period, we will replace damaged parts (excluding human damage).

Related Products

Efficient Turntable Automatic High Speed Sorting Checkweigher

Intelligent Metal Detector for Industrial Factory Supply

High Precision Checkweigher For Pharmaceutical Formulation

Bottled Canned Capsules Digital Metal Detection Machine

Bottled Capsule Checkweigher and Metal Detector Combo

Strip Packaging Assembly Line Efficient Check Weigher Price

Hot Labels: sauce,pipeline type,digital metal detection machine,metal detector,high quality,conveyor,belt,metal detector for food,supply,China,price,factory